HDPE Marine-Grade Sheet

1. Basic Characteristics of HDPE Marine-Grade Sheet

- Excellent Corrosion Resistance: HDPE (High-Density Polyethylene) inherently possesses outstanding chemical resistance, enabling marine-grade HDPE sheets to withstand seawater erosion and corrosion from various chemicals in marine environments. This ensures long-term structural and performance stability, reducing replacement frequency and maintenance costs. For example, in marine aquaculture facilities, prolonged exposure to seawater and substances secreted by marine organisms does not easily lead to corrosion.

- High Strength and Rigidity: The marine environment is harsh, with external forces such as wind, waves, and tides. HDPE marine-grade sheets have sufficient strength and rigidity to withstand these forces, ensuring stability in marine structures. In applications like marine walkways, which need to bear the weight and pressure of personnel movement and equipment placement, HDPE sheets effectively meet these demands.

- Wear Resistance: In marine applications, such as walkways and fish rafts in aquaculture facilities, components are frequently subjected to friction from marine organisms, water flow erosion, and wear from equipment and personnel. The wear resistance of HDPE marine-grade sheets ensures their functionality over extended periods, minimizing damage due to abrasion.

- UV Resistance: The marine environment is characterized by strong ultraviolet (UV) radiation, which can cause material aging and performance degradation over time. HDPE marine-grade sheets, either through special treatment or inherent properties, exhibit UV resistance, allowing prolonged use in marine environments without significant aging.

2. Common Applications of HDPE Marine-Grade Sheet

- Marine Aquaculture:

- Marine Walkways and Fish Rafts: Used to construct walkways and fish rafts in marine aquaculture, providing platforms for farmers to walk and operate. In deep-sea and shallow-sea aquaculture for species like yellow croaker, scallops, and kelp, these walkways and rafts are essential for daily management, feed distribution, and harvesting.

- Protective and Support Structures for Aquaculture Facilities: Used as protective barriers, support frames, and other structural components to safeguard aquaculture areas and maintain the shape and stability of facilities.

- Marine Engineering Auxiliary Facilities:

- Non-Slip Walkway Manufacturing: Used in marine vessels, offshore oil platforms, and other facilities to manufacture non-slip walkways, ensuring safe personnel movement.

- Temporary Structures: Employed in temporary marine operations, such as scientific expeditions and maritime rescue, for constructing platforms, gangways, and other temporary structures.

3. Related Manufacturers and Product Features

- Selected Manufacturers and Product Characteristics:

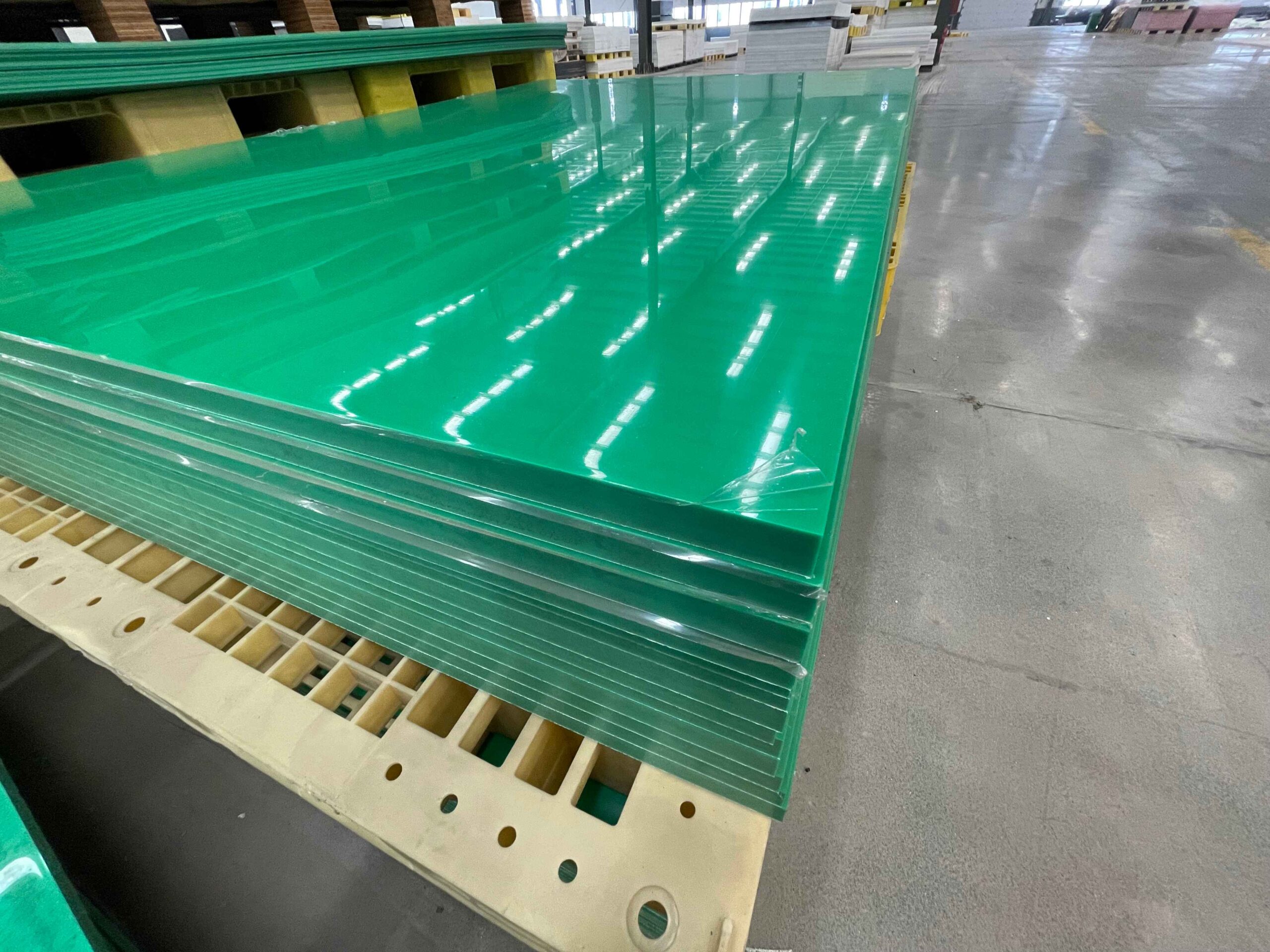

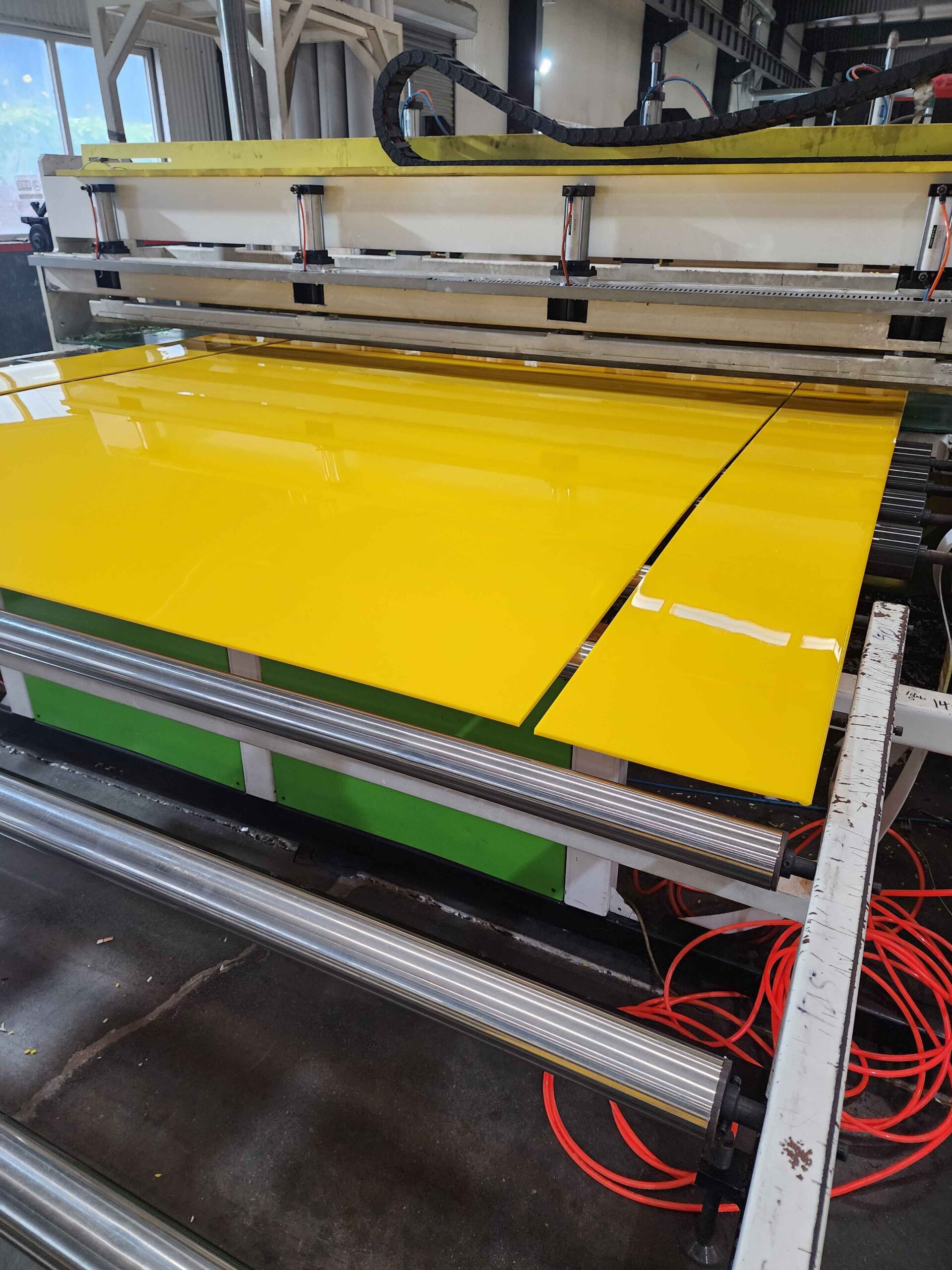

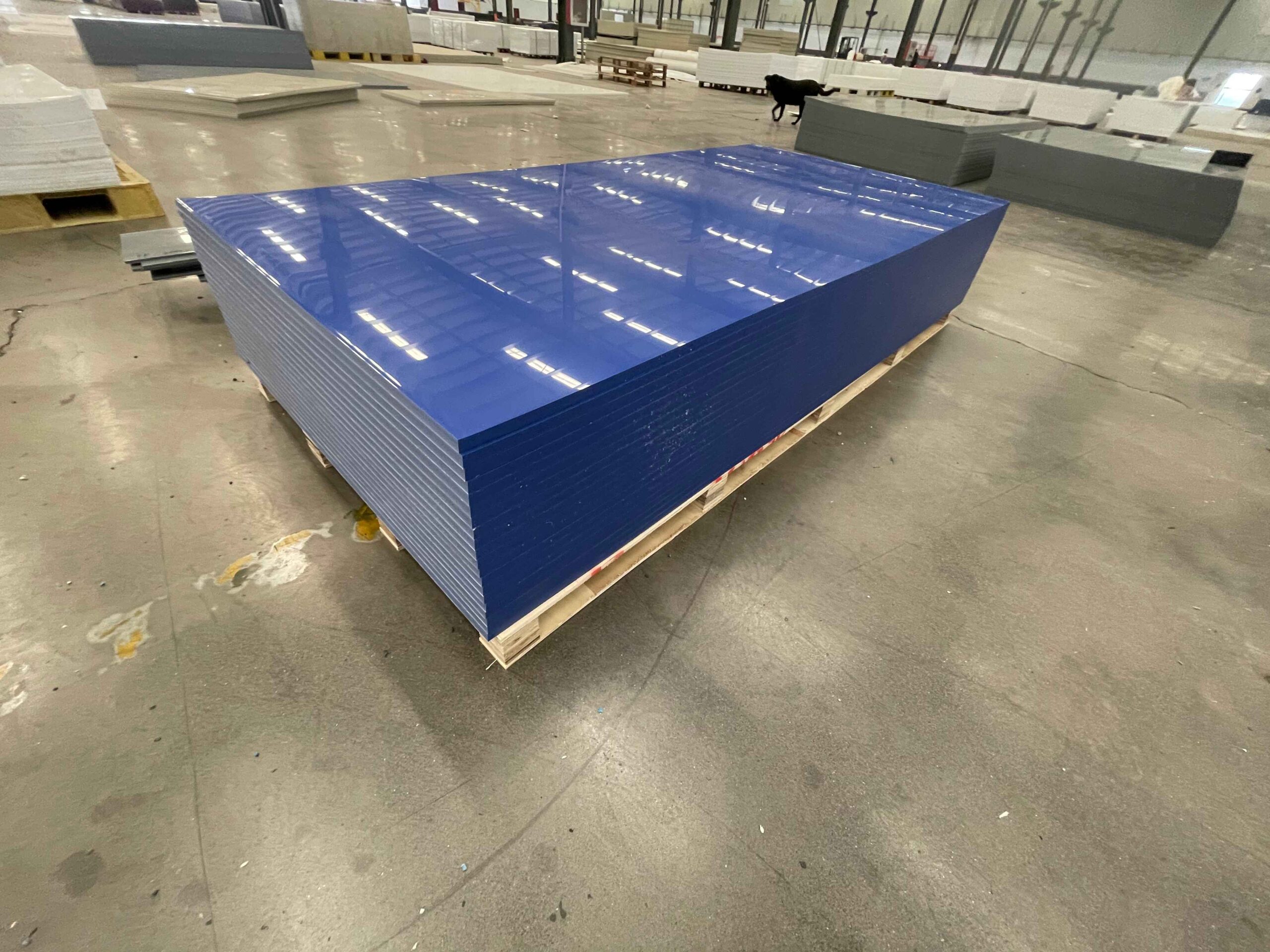

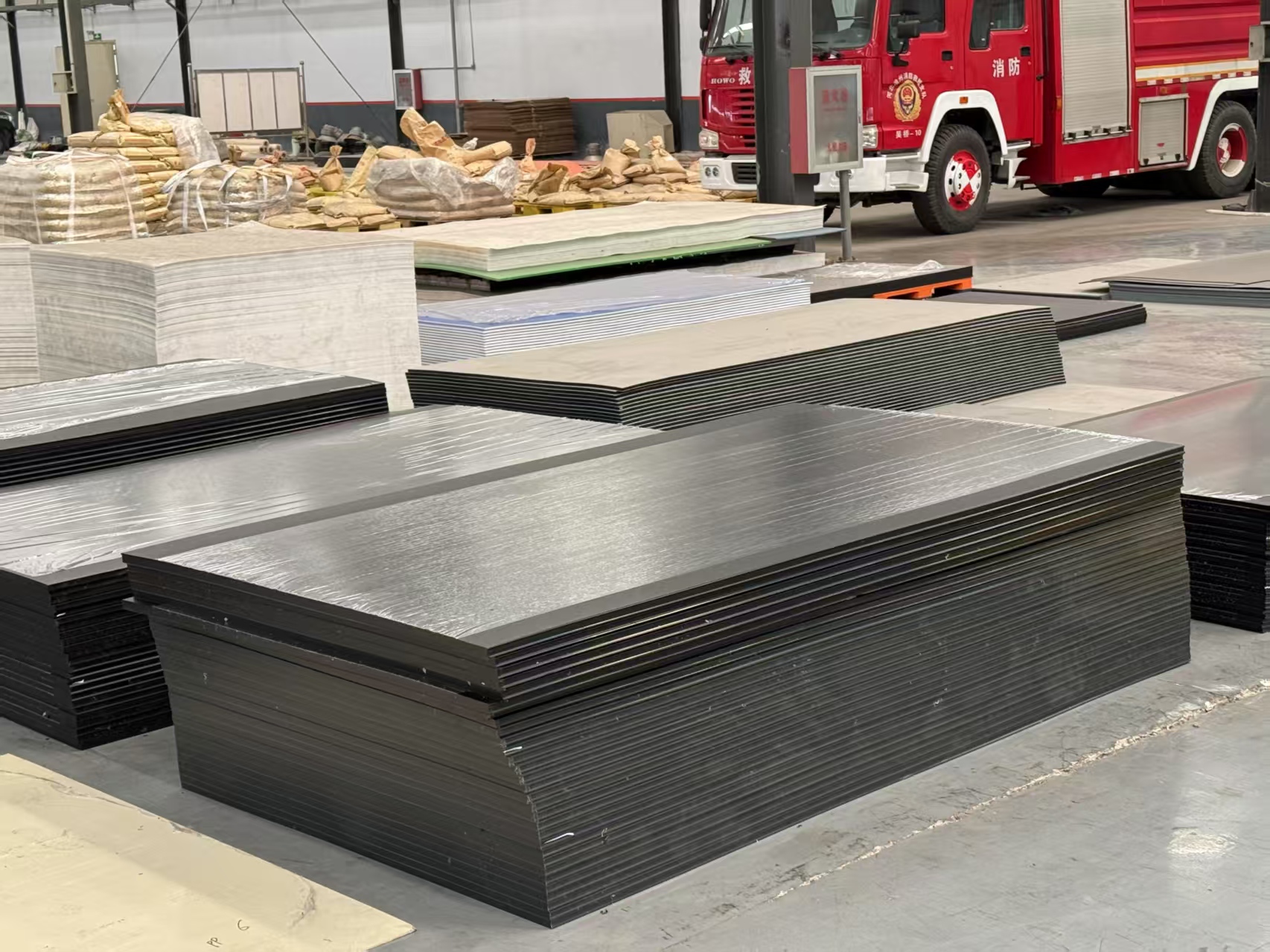

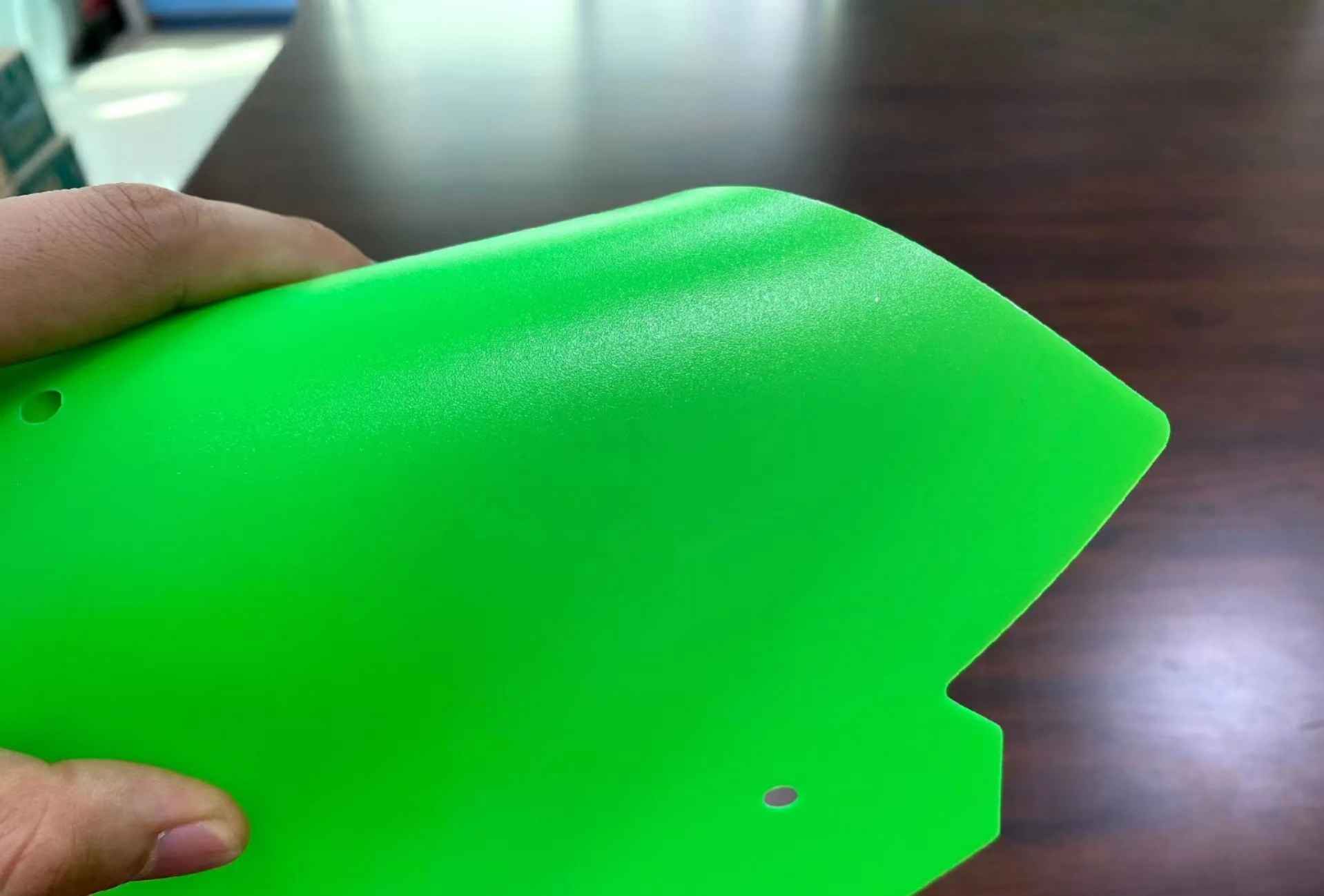

- Our HDPE Marine Walkways: Produced using PE100-grade raw materials through advanced co-extrusion processes. The outer layer can be customized in colors (e.g., blue, yellow, green) with non-slip functionality, while the inner layer is black. The production line is highly automated, energy-efficient, and offers high production efficiency. The walkways are of high quality, with an extrusion output of 400–500 kg/h, a line speed of approximately 0.2–2 m/min, and an extruder center height of 1050 mm.