HDPE Anti-Slip Road Mat is a heavy-duty ground protection mat made from high-density polyethylene (HDPE), designed to create temporary access roads and work platforms on soft, muddy or sensitive ground. With high load-bearing capacity, anti-slip surface patterns and excellent impact and wear resistance, it provides a safe and stable surface for vehicles, cranes and construction equipment in demanding environments.

1. Product Features

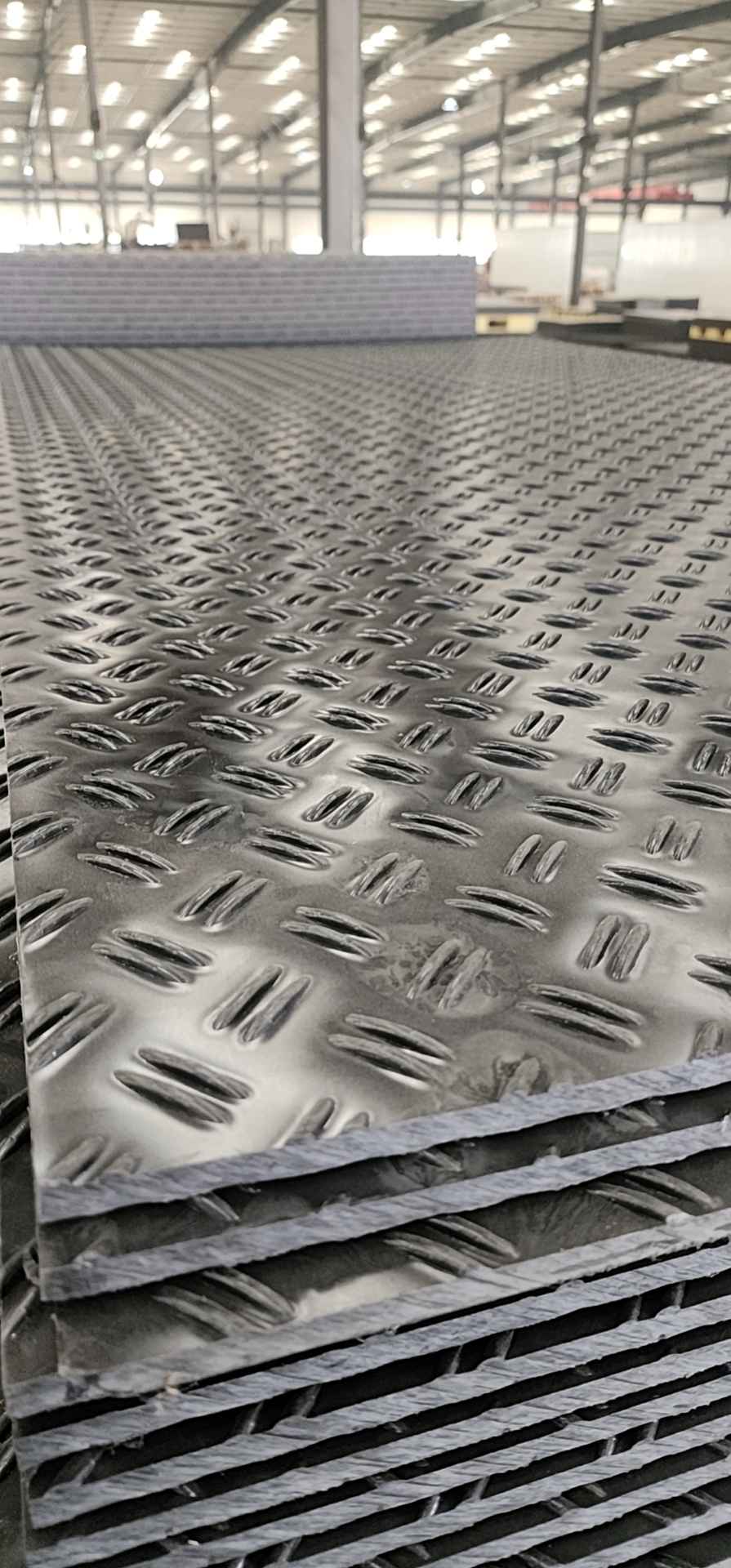

- Durable HDPE Material: Manufactured from tough HDPE, the mats offer excellent impact, abrasion and weather resistance. They are suitable for repeated use on busy construction sites and in rental fleets.

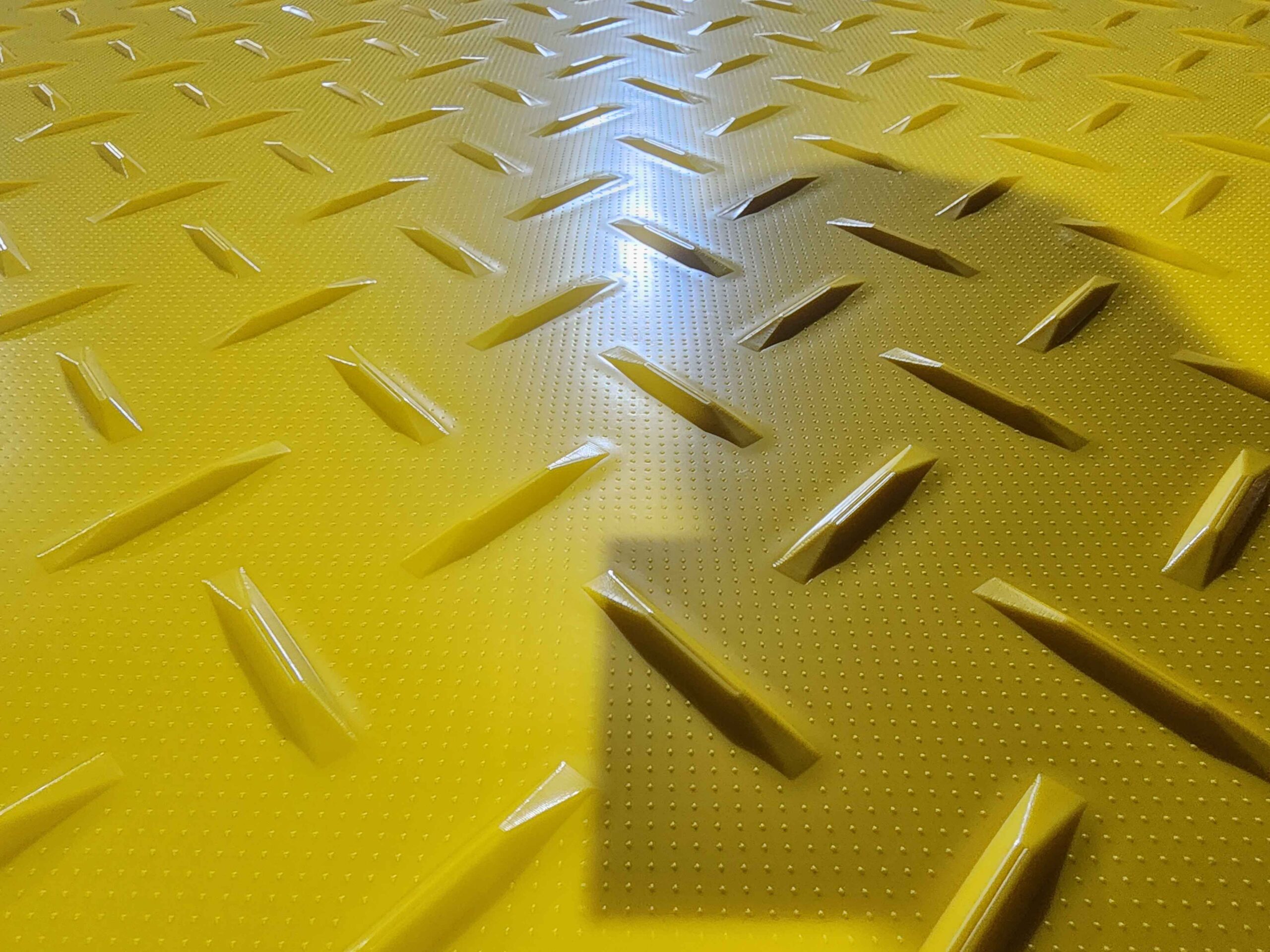

- Anti-Slip Surface: Both sides can be designed with aggressive tread patterns to enhance grip for vehicle tyres and personnel, reducing the risk of slipping on wet, oily or uneven ground.

- High Load-Bearing Capacity: Properly supported, HDPE road mats can carry heavy vehicles, cranes and equipment, helping to prevent sinking, rutting and ground damage on soft soil.

- Lightweight & Easy to Handle: Compared to steel plates, HDPE mats are much lighter, making manual handling or handling with light lifting equipment easier and reducing installation time and labour intensity.

- Chemical and Corrosion Resistant: Resistant to water, mud, many chemicals and road contaminants, the mats will not rust or rot, even in harsh outdoor conditions.

- Reusable & Cost-Effective: Designed for multiple deployment cycles, HDPE road mats can be used again and again, significantly lowering the cost per project compared with disposable ground protection solutions.

2. Functional & Environmental Characteristics

- Ground Protection: Distributes vehicle and equipment loads over a larger area, protecting lawns, asphalt, paving, sand and other sensitive surfaces from damage.

- Improved Site Safety: Creates level, anti-slip working and driving surfaces, helping to reduce accidents caused by vehicles getting stuck or workers slipping in mud.

- Fast Deployment: Standard-sized mats can be quickly laid and connected to form temporary roads or platforms, reducing site preparation time.

- Environmental Responsibility: HDPE material is recyclable and does not leach harmful substances during normal use, making it a more eco-friendly choice for temporary road construction.

3. Typical Applications

- Construction Sites: Temporary access roads and work pads for trucks, excavators, concrete pumps and cranes on soft or muddy ground.

- Temporary Parking Areas: Creating stable parking surfaces for events, construction logistics, or overflow parking in fields and open areas.

- Lawn and Landscape Protection: Protecting grass and landscaped areas from vehicle and foot traffic during events, maintenance work or construction.

- Oil & Gas, Mining and Utilities: Access roads and working platforms in remote, marshy or sandy locations, reducing the risk of vehicles becoming stuck.

- Events, Shows and Exhibitions: Walkways, equipment routes and temporary flooring in stadiums, parks, exhibition grounds and outdoor venues.

- Beach and Coastal Projects: Providing access for vehicles and personnel on sand during coastal construction, pipeline work or wind turbine installation.

4. Handling and Use Tips

- Correct Installation: Place mats on prepared ground and connect them according to the recommended pattern to achieve stable load distribution.

- Load Assessment: Select mat thickness and layout according to vehicle type, axle load and ground conditions to ensure safe operation.

- Cleaning and Storage: Remove mud and debris after use and store the mats in a dry, ventilated area to extend service life.

- Safe Handling: Use proper lifting equipment or manual handling methods and follow site safety procedures when moving or repositioning mats.

5. Customization & Supply Options

HDPE anti-slip road mats can be supplied in different sizes, thicknesses, surface patterns and connection systems according to your application and fleet requirements. Options include:

- Standard or customized mat dimensions

- Single- or double-sided anti-slip patterns

- Different thicknesses for light, medium and heavy-duty loads

- Various connection methods for fast deployment and secure linking

- Color options for branding or site visibility

Share your typical ground conditions, vehicle types and loading requirements, and we can recommend suitable HDPE Anti-Slip Road Mat specifications and provide a competitive quotation for your projects or rental fleet.

Summary

HDPE Anti-Slip Road Mats offer a robust, reusable and environmentally friendly solution for temporary access roads and ground protection. They help contractors, event organizers and operators in oil, gas, mining and construction achieve safe and efficient site access while minimizing damage to the underlying ground.