HDPE Flame-Retardant Board is a modified high-density polyethylene sheet engineered to provide reliable flame-retardant performance while maintaining the toughness, chemical resistance and processability of standard HDPE. It is widely used in environments where plastic materials must resist ignition, slow flame spread and maintain structural integrity under elevated temperatures.

Typical Specifications of HDPE Flame-Retardant Board

| Item | Typical Value / Range | Notes |

|---|---|---|

| Material | Flame-retardant HDPE (modified high-density polyethylene) | Halogen-free or halogen-containing formulations available on request |

| Density | Approx. 0.94 – 0.97 g/cm³ | Lower density compared with metal panels, easier handling |

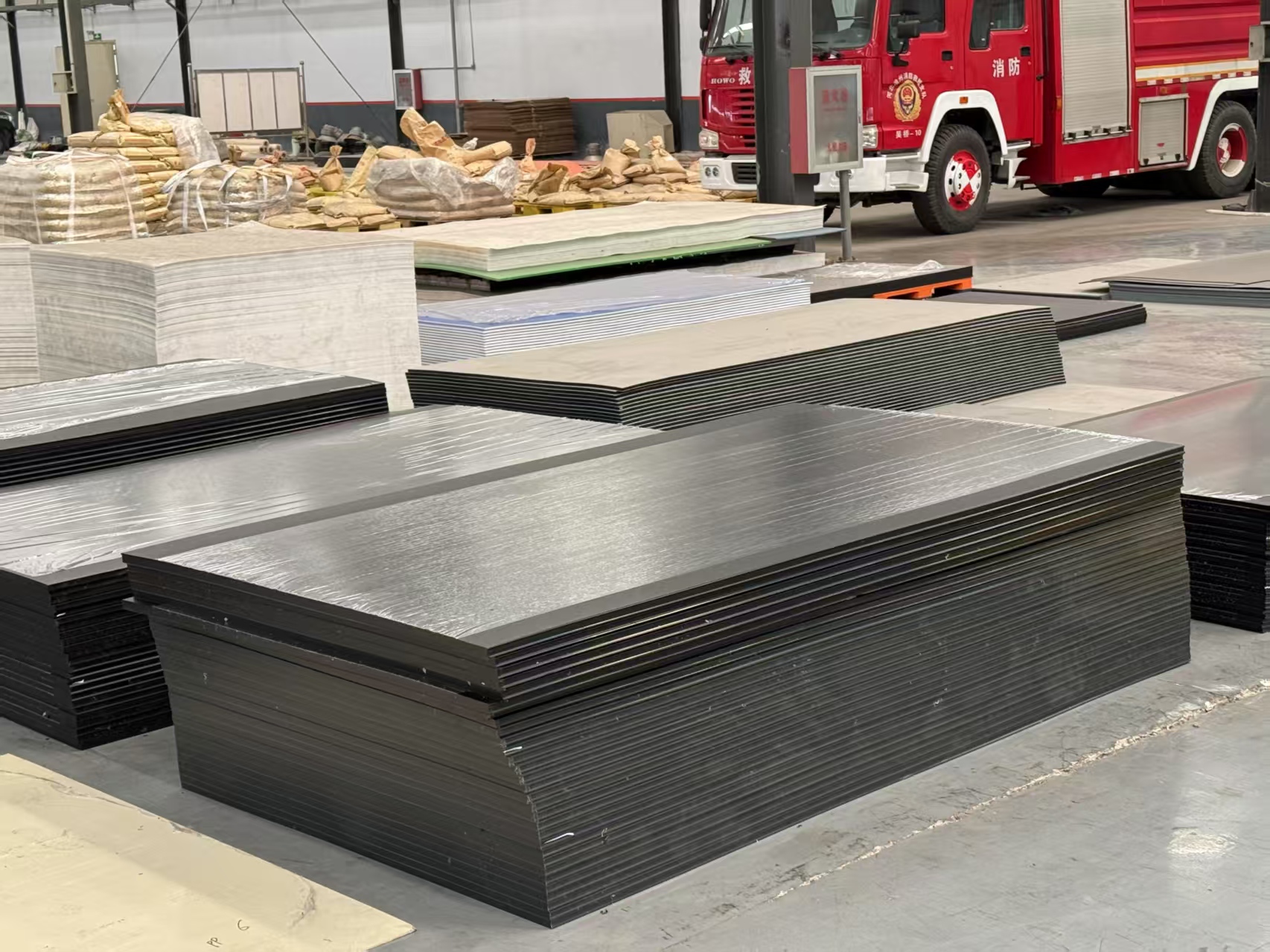

| Standard Thickness | 3 – 30 mm | Other thicknesses can be customized |

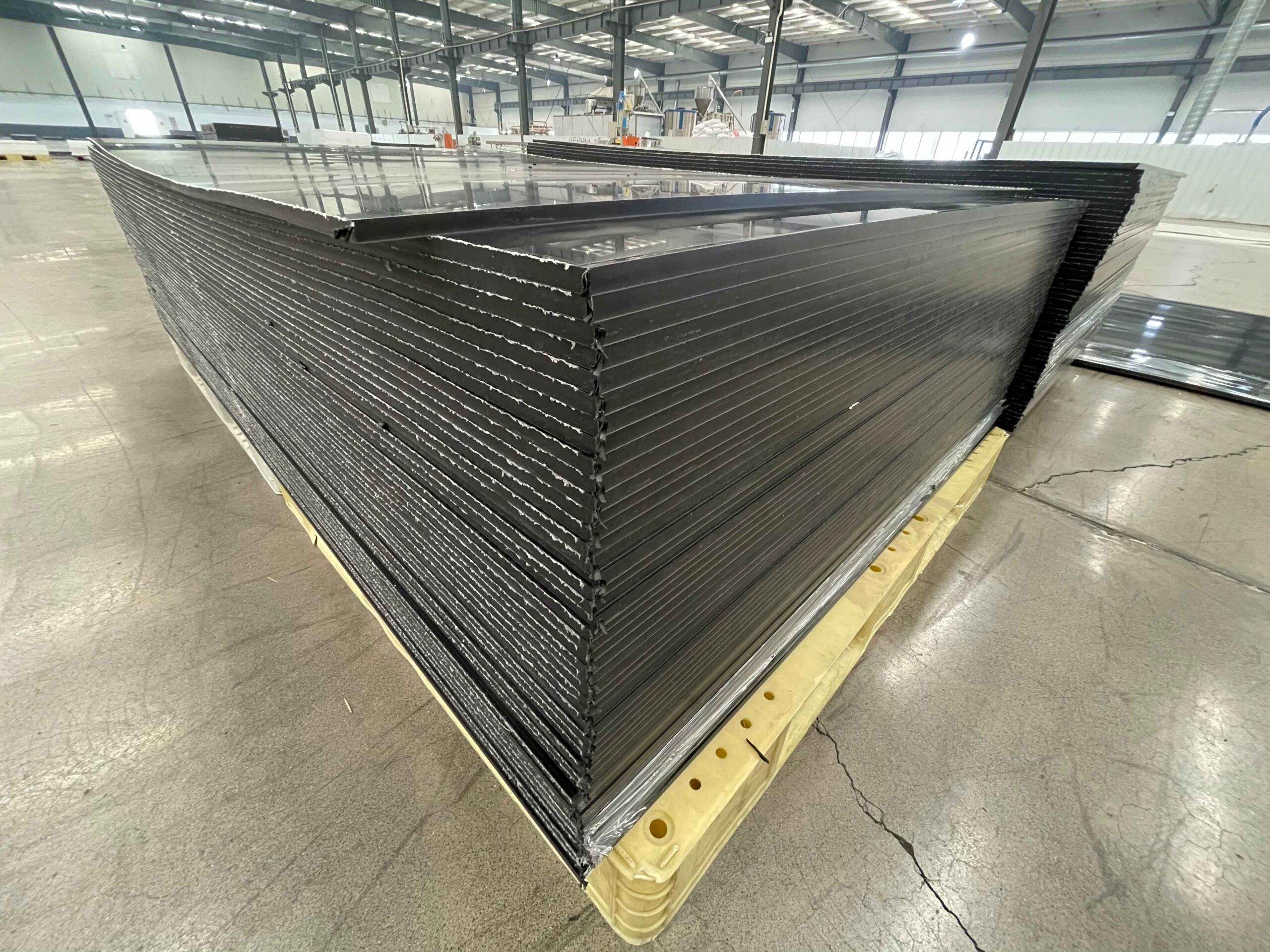

| Standard Sheet Size | 1000 × 2000 mm, 1220 × 2440 mm | Max. sheet size and cut-to-size service available |

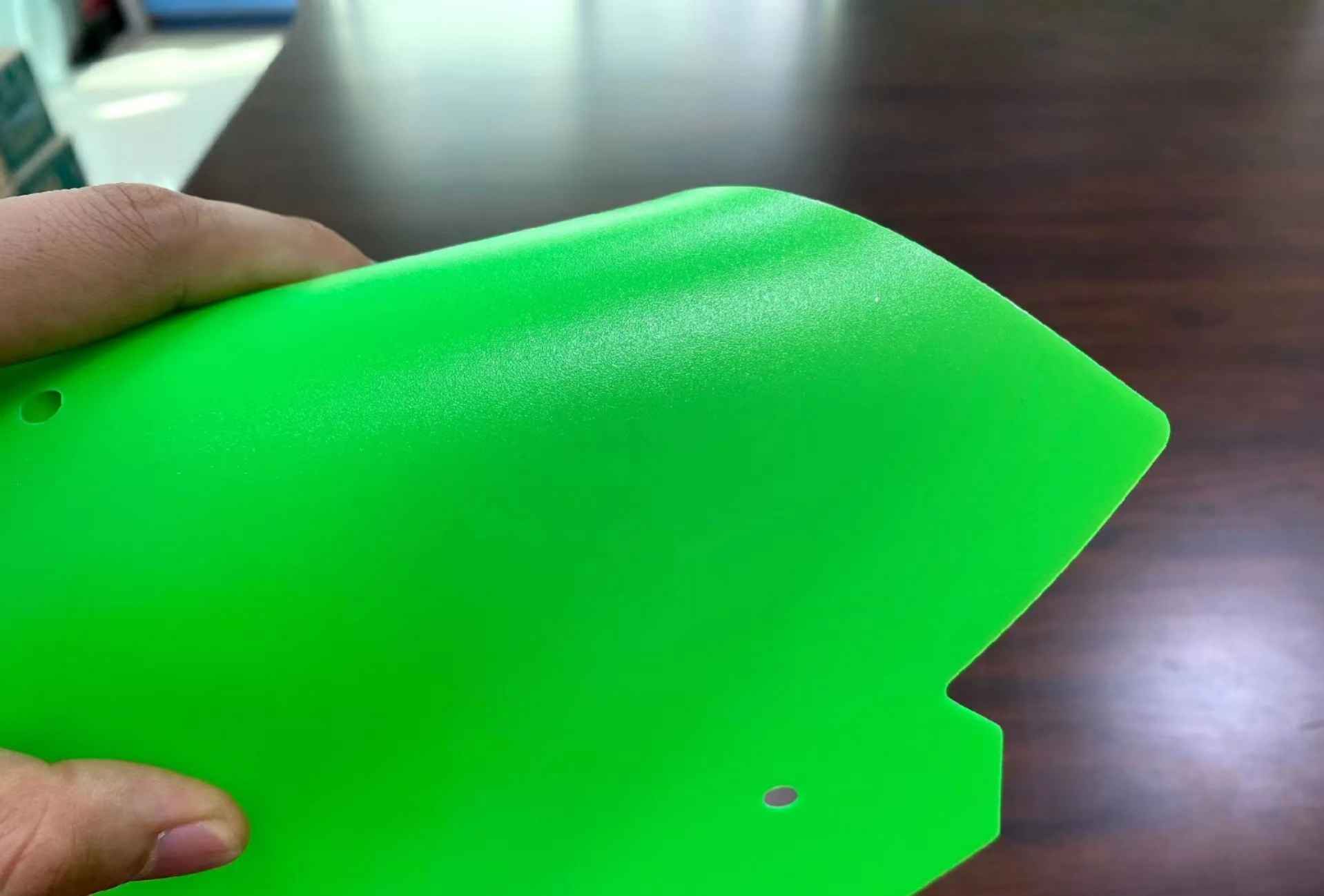

| Color | Black, grey, white or custom | Color coding for zones or branding is possible |

| Flame-Retardant Grade | Custom (e.g. UL94 HB / V-2 / V-0 equivalent) | Final grade depends on formulation and thickness |

| Surface Finish | Smooth, matte or textured | Embossed or anti-slip textures available on request |

| Service Temperature | Approx. -50 °C to +80 °C | Actual range depends on load and safety factor |

| Chemical Resistance | Good resistance to many acids, alkalis and salts | Not recommended for strong oxidizing agents without prior testing |

| Electrical Properties | High volume resistivity, good dielectric strength | Suitable for use as insulating and protective panels |

| Processing Methods | Cutting, drilling, routing, CNC machining | Can be fabricated into custom parts according to drawings |

1. Key Performance Features

- Effective flame-retardant performance

Produced with halogen-free flame retardants or custom FR formulations, the board can achieve common industry flame ratings such as UL94 V-0 / V-2 / HB depending on customer requirements. It delays ignition, reduces dripping and limits flame propagation. - Maintains HDPE toughness

Unlike many flame-retardant plastics that become brittle, FR-HDPE retains excellent impact resistance and flexibility, suitable for demanding installation or repeated mechanical stress. - Chemical & corrosion resistance

Resistant to acids, alkalis, salts and moisture, making it suitable for corrosive industrial environments and outdoor installations. - Low friction & wear resistance

Features a naturally low coefficient of friction and good sliding characteristics, suitable for components that require both flame-retardancy and wear resistance. - Electrical insulation

HDPE inherently provides strong dielectric properties and volume resistivity, making flame-retardant HDPE suitable for electrical cabinet lining, safety partitions and other protective structures. - Low water absorption & stable dimensions

Low moisture uptake ensures stable performance in humid or outdoor environments without swelling or deformation.

2. Advantages Compared with Standard HDPE

- Enhanced fire safety: Reduces ignition risk and limits damage in case of accidental fire.

- Better protection for electrical and industrial equipment: Suitable for applications requiring both insulation and flame retardancy.

- Better compliance: Helps meet safety standards in buildings, public facilities, chemical plants and transportation equipment.

- Customizable performance: Flame-retardancy level, color, surface texture, and anti-static properties can all be modified.

3. Typical Applications

- Electrical & power systems

Panels, protective covers, insulation plates and structural components inside electrical cabinets, switch rooms and substations. - Chemical & industrial plants

Flame-retardant partitions, safety shields, duct covers and anti-corrosion boards in areas exposed to acids, alkalis and chemicals. - Public facilities and transportation

Wall panels, protective boards and safety components where flame-retardant materials are required by regulation. - Machinery & equipment manufacturing

Wear-resistant and FR-safe components such as sliders, bushings, guards and covers. - Food, packaging & logistics

Non-toxic, low-absorption boards suitable for hygienic environments with elevated safety requirements.

4. Customization Options

HDPE flame-retardant boards can be manufactured according to customer specifications:

- Custom thickness, width and sheet size

- Flame-retardant rating: UL94 V0 / V2 / HB or custom formulations

- Halogen-free / low-smoke FR options

- Optional anti-static or conductive properties

- Surface finishes: smooth, matte, textured or embossed

- Color customization for safety coding or branding

Share your working environment, required flame-retardant grade and sheet dimensions, and we will recommend a suitable HDPE Flame-Retardant Board solution and provide a competitive quotation.