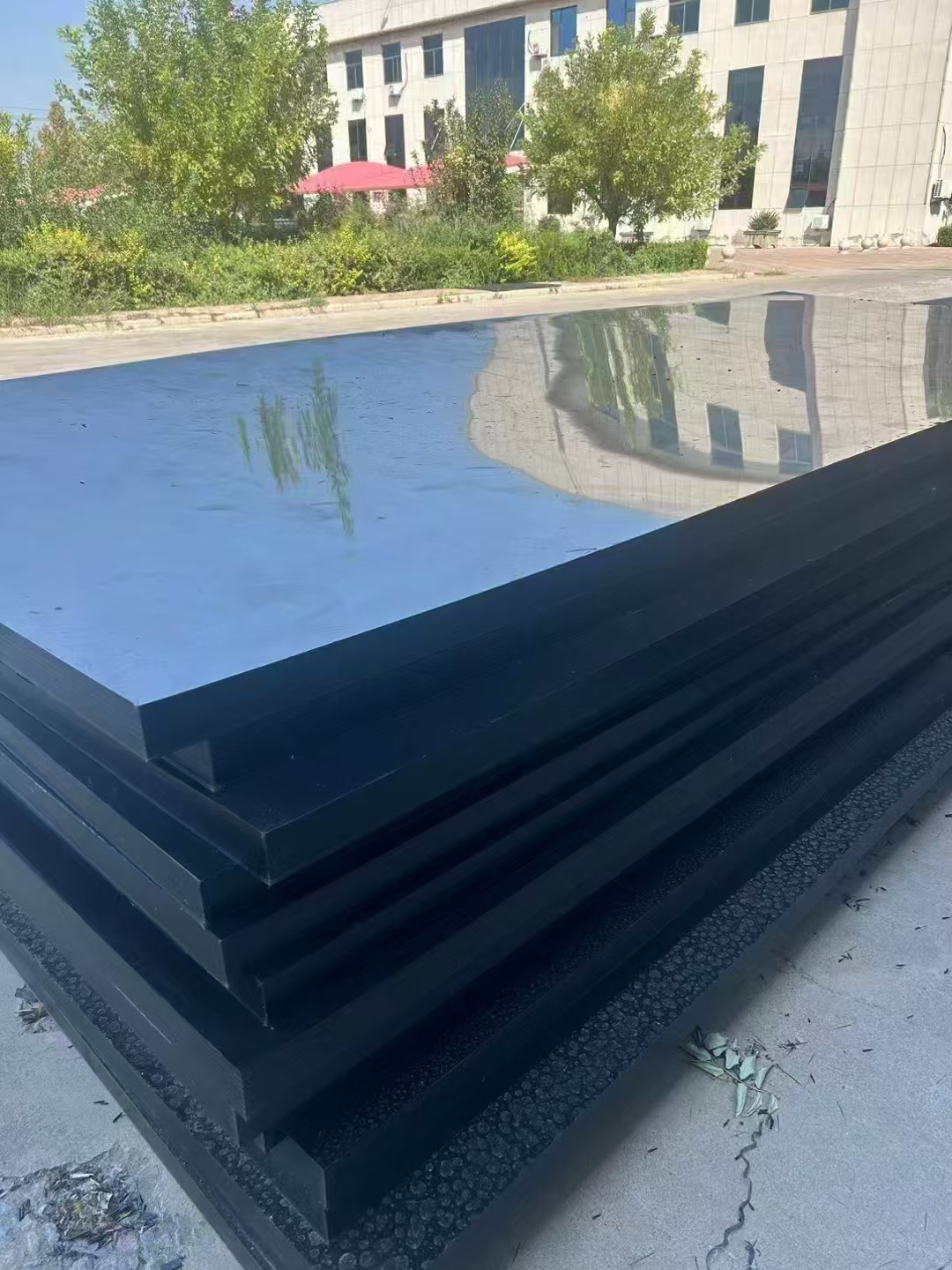

Ultra-High Molecular Weight Polyethylene (UHMWPE) Sheet is a high-performance engineering plastic with extremely long molecular chains, giving it outstanding wear resistance, impact strength and chemical stability. Compared with conventional PE and many metal materials, UHMWPE offers much longer service life under sliding wear and impact, and is widely used for industrial liners, wear strips, guides and other components in harsh working environments.

1. Core Performance Advantages

- Exceptional wear resistance

UHMWPE has one of the best wear resistance levels among plastics and can outperform many metals under sliding friction. It is especially suitable for chutes, hoppers and conveying systems where bulk materials cause continuous abrasion. - High impact toughness

The material combines high impact strength with good toughness and does not crack easily under shock or repeated impact, even at low temperatures. This makes it suitable for impact pads, fenders and protective plates. - Low friction & self-lubricating

UHMWPE offers a low coefficient of friction and a smooth sliding surface, providing good self-lubricating performance. It can reduce or even eliminate the need for additional lubrication in many applications. - Chemical and corrosion resistance

Resistant to many acids, alkalis, salts and a wide range of industrial media, UHMWPE sheets can be used in corrosive environments such as chemical, mining and power plants. - Non-absorbent and hygienic

Very low water absorption, non-adhesive to most materials, and available in food-grade grades, which makes UHMWPE suitable for applications in food processing and other hygiene-sensitive industries. - Lightweight and easy to machine

With a density of around 0.93–0.97 g/cm³, UHMWPE is much lighter than steel while still providing high strength. It can be cut, drilled, milled and fabricated into various shapes according to drawings.

2. Main Application Areas

- Industrial wear protection

Used as liners for hoppers, chutes, truck beds, silos and scraper conveyors in mining, ports, cement, coal and bulk material handling to reduce sticking, wear and noise. - Chemical and power industries

Wear- and corrosion-resistant liners for tanks, channels and flue gas desulfurization systems, as well as structural components in corrosive service. - Mechanical engineering

Gears, bushings, guide rails, sliders and other wear parts, replacing metal to reduce noise, friction and the need for lubrication. - Material handling and logistics

Boards and profiles for conveyor systems, packaging machinery and handling equipment where low friction and long wear life are required. - Special environments

Fender pads, dock bumpers, impact protection plates and other components used in harsh outdoor or low-temperature conditions.

3. Customization & Machining

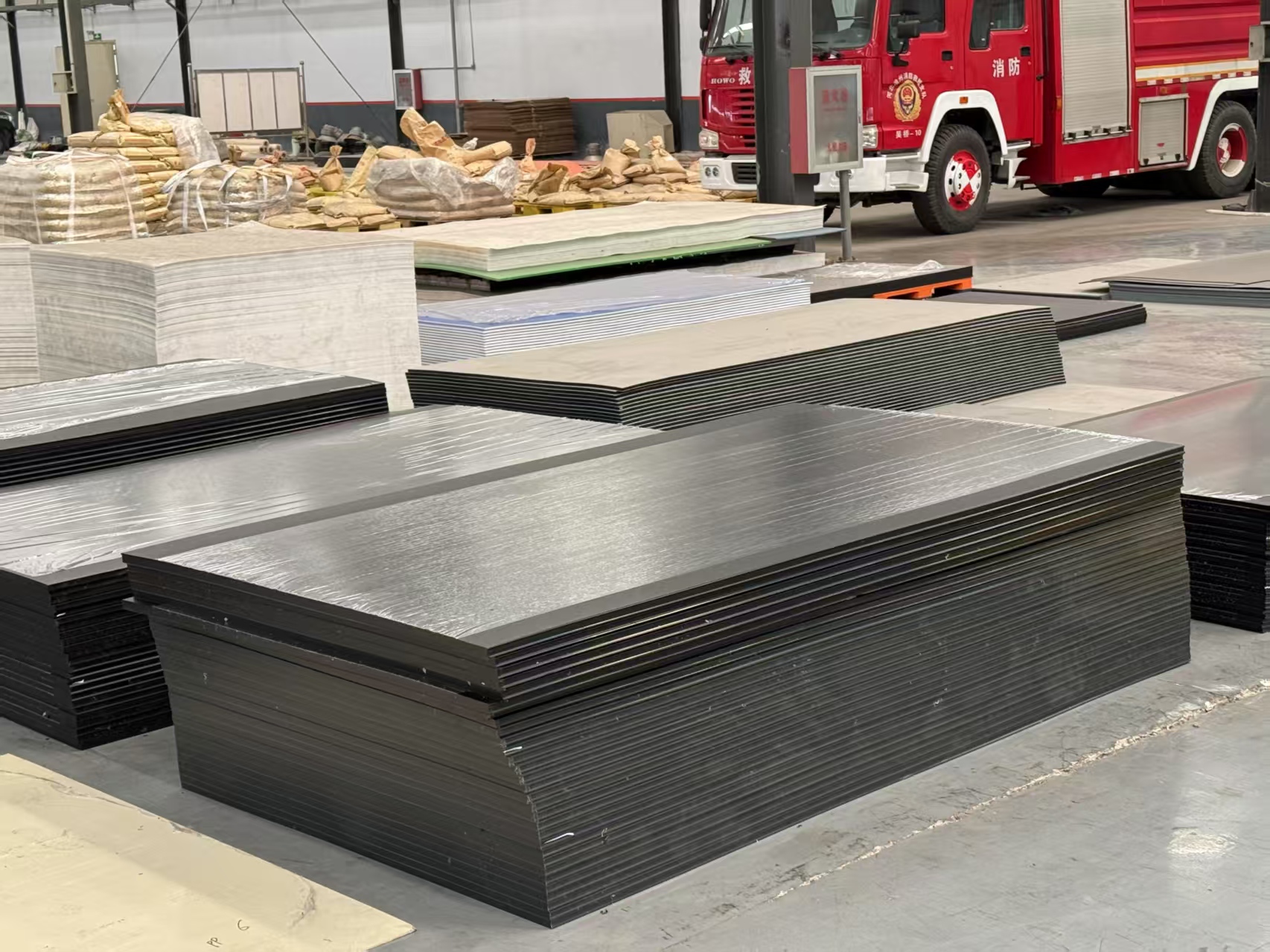

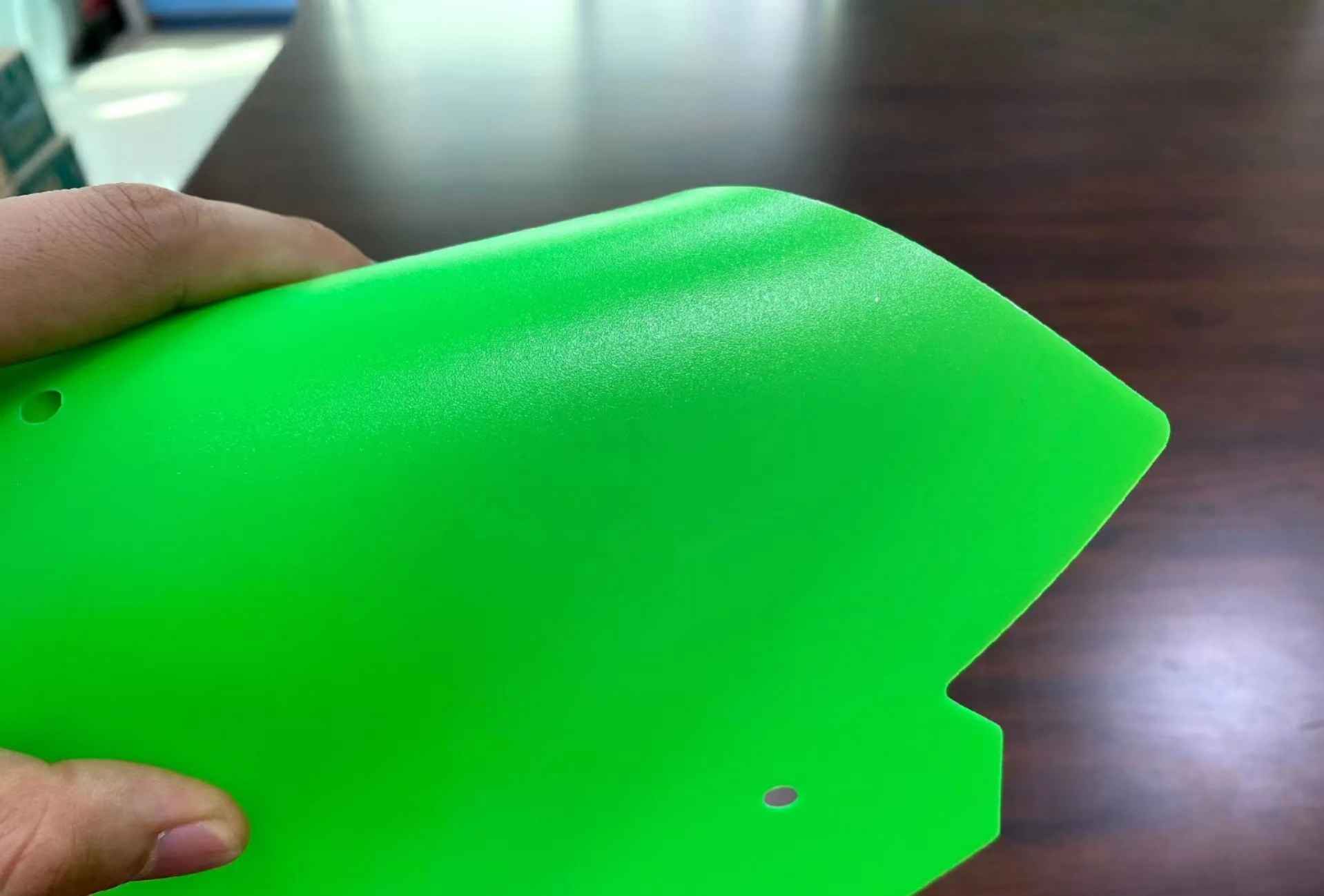

UHMWPE sheets can be supplied in different thicknesses, sizes, grades and colors, and can be further processed into finished parts according to customer drawings.

- Standard and customized sheet dimensions

- Different grades (general industrial, higher-wear grades, food-contact grades, etc.)

- Cut-to-size plates, liners and machined parts

- Edge chamfering, countersunk holes, slots and complex CNC machining

Share your application, working environment (temperature, contact media), required thickness and dimensions, and we can recommend suitable UHMWPE sheet grades and provide a competitive quotation for your project.

Summary

Ultra-High Molecular Weight Polyethylene (UHMWPE) Sheet combines outstanding wear resistance, impact toughness, low friction and corrosion resistance in one material. It is an ideal choice for industrial wear protection and sliding components, helping users extend equipment life, reduce maintenance and improve operating efficiency.