Overview of HDPE Boards

High-Density Polyethylene (HDPE) boards are premium engineering plastic materials known for their versatility and durability.

1. Key Characteristics

Mechanical Properties

- High Strength and Rigidity: HDPE boards offer excellent stiffness, hardness, and strength, capable of withstanding significant pressure and loads in structural applications, such as mechanical components or construction frameworks. However, their notched impact toughness is moderate.

- Low Density: With a density less than 1 g/cm³, HDPE boards are lightweight, making them advantageous in weight-sensitive applications like aerospace or portable equipment (though subject to other limiting factors).

- Stable Performance: Ultra-high molecular weight HDPE has extremely low water absorption, ensuring consistent mechanical properties across a wide range of temperatures. This stability is critical for components used in environments with significant temperature fluctuations, such as outdoor infrastructure.

Wear Resistance

- Superior Durability: HDPE boards are six times more wear-resistant than carbon steel, making them ideal for high-wear applications like silo liners, coal bunker liners, and chute liners. They effectively reduce material abrasion, extending equipment lifespan.

Chemical Properties

- Chemical Resistance: HDPE boards resist most acids, alkalis, salts, and industrial chemicals, except strong oxidizing agents like concentrated sulfuric acid or nitric acid. This makes them suitable for chemical-intensive industries such as chemical processing and electroplating, where they are used for corrosion-resistant linings.

- Moisture Resistance: Non-hygroscopic with excellent water vapor barrier properties, HDPE boards are ideal for packaging applications, protecting contents from moisture in fields like food and pharmaceuticals.

Surface Properties

- Low Friction and Non-Stick: With high surface tension, low friction coefficient, and non-polar properties, HDPE boards resist adhesion and scaling. This ensures smooth material flow and easy cleaning in applications like food processing equipment.

Electrical Properties

- Excellent Insulation: HDPE boards have high insulation resistance and dielectric strength, making them suitable for electrical components like cable protection tubes, preventing electrical hazards.

Temperature Adaptability

- Wide Temperature Range: Functional from -70°C to 90°C, HDPE boards perform reliably in both low- and high-temperature environments, such as refrigeration systems or protective components in elevated temperatures.

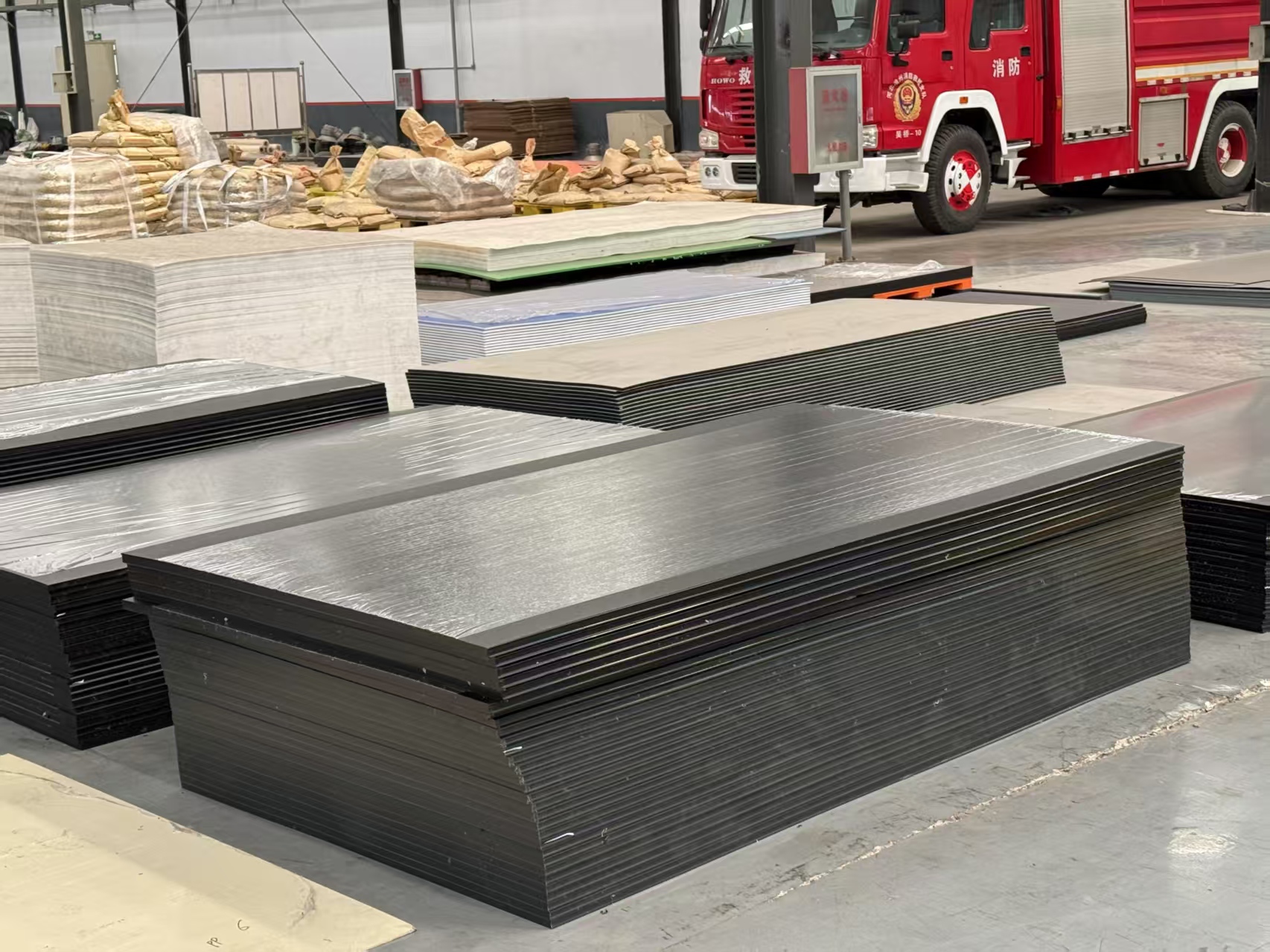

2. Specifications

- Dimensions: Thickness ranges from 1–40 mm, with a maximum width of 3000 mm and unlimited length. Sheets can be rolled for packaging (maximum roll diameter: 1000 mm).

- Customizability: Boards can be cut and processed to meet specific application requirements, such as producing cutting boards or liners of varying sizes.

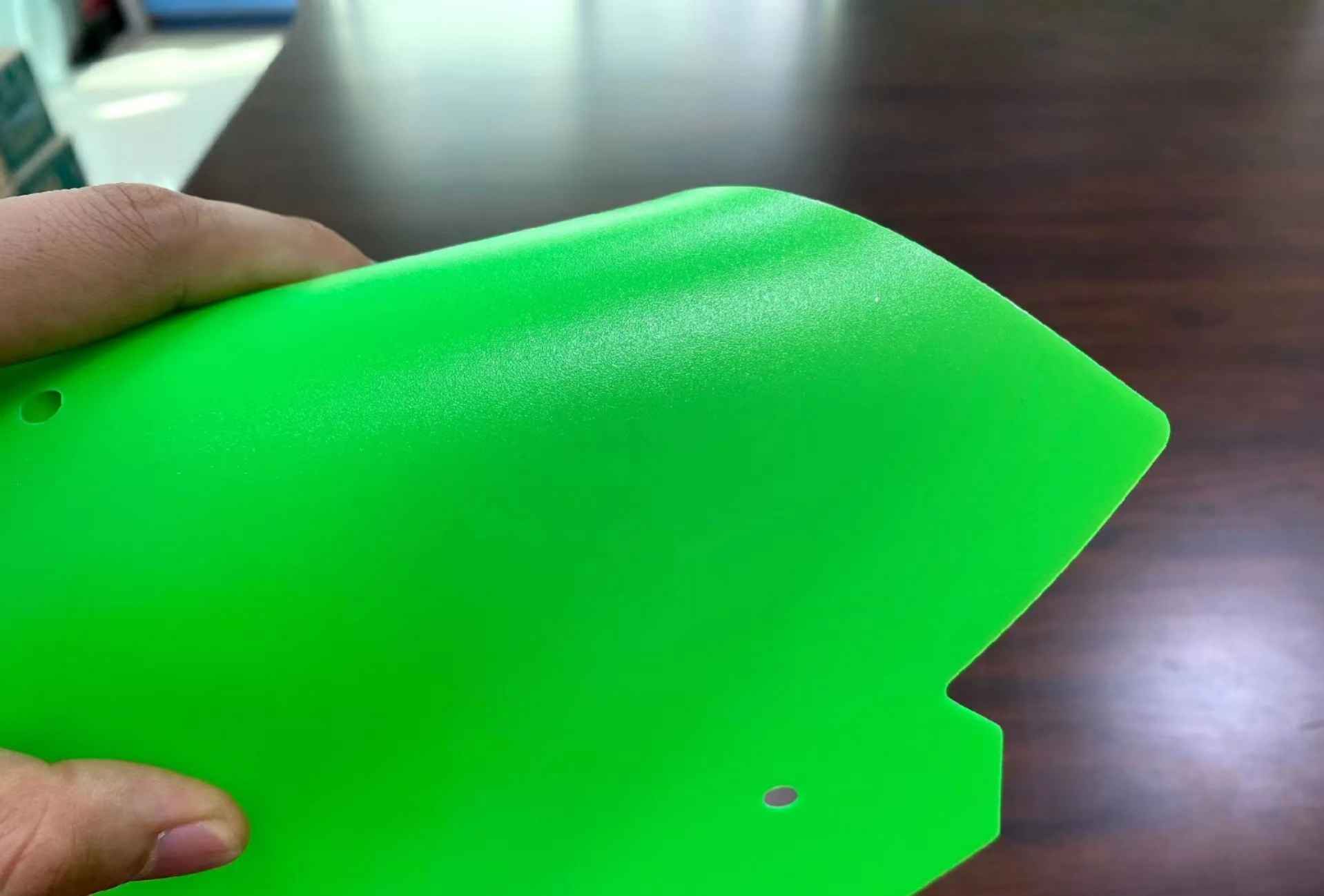

3. Color Options

- Available in a wide range of user-specified colors to meet aesthetic and functional needs, such as in furniture, toys, or other products requiring customized appearances.

4. Applications

Industrial Applications

- Chemical, Mechanical, and Power Industries: HDPE boards are used for corrosion-resistant linings, pipelines, mechanical components, cable protection tubes, and electrical enclosures.

- Coal Industry: Employed as liners for coal bunkers, silos, chutes, and conveyor belt slide plates to minimize wear from abrasive materials.

- Construction: Used as liners for cement raw material and finished product silos to protect against material erosion and wear.

- Paper Industry: Applied in repair boards, water absorption box panels, and paper machine components, leveraging their wear and chemical resistance.

Food Industry

- HDPE boards are ideal for food-grade cutting boards, chopping blocks, meat dividers, and butcher boards due to their non-toxic, smooth, corrosion-resistant, and non-absorbent properties. They ensure hygiene, safety, durability, and knife-friendliness while offering an attractive appearance and long service life.

Other Applications

- Electronics and Medical: Used for medical device components, sensors, and seals, ensuring hygiene and safety.

- General Manufacturing: Employed in cutting boards, sliding profiles, containers, guide rails, truck bed liners, and dump truck liners.

- Consumer and Commercial Products: Found in advertising boards, promotional materials, display units, toys, trash bins, and various everyday plastic products.