Overview of HDPE100 Grade Boards

HDPE100 Grade Boards are high-performance polyethylene sheets produced from PE100 resin. Compared with standard HDPE, PE100 offers significantly higher tensile strength, better long-term creep resistance, improved toughness and superior environmental stress-crack resistance. This makes HDPE100 boards ideal for heavy-duty industrial, chemical, structural, marine, and cold-temperature applications where long service life and material stability are essential.

1. Key Characteristics

Physical Properties

HDPE100 is a high-crystallinity, non-polar engineering thermoplastic with a natural milky-white appearance. Even at extremely low temperatures (down to –70°C), the material maintains excellent toughness, impact resistance and dimensional stability. HDPE100 boards will not crack or embrittle in cold environments, making them suitable for outdoor, refrigerated or low-temperature industrial conditions.

- Available Specifications: Thickness 3–40 mm; width 1000–2400 mm; length fully customizable.

- High impact strength: Performs reliably under repeated impact or vibration.

- Dimensional stability: Minimal deformation under temperature changes and long-term load.

Chemical Properties

HDPE100 boards have excellent chemical resistance against most acids, alkalis, salts, detergents, and industrial process chemicals. They do not absorb water and exhibit very low vapor permeability, ensuring environmental stability even in humid or corrosive environments.

- Moisture-proof: Non-hygroscopic and ideal for wet, marine or chemical environments.

- Chemical resistant: Suitable for chemical storage equipment and process lines.

- Limitations: Not suitable for oxidizing acids (e.g., concentrated nitric acid) or strong aromatic hydrocarbons (e.g., xylene).

Electrical Properties

HDPE100 has high dielectric strength and stable electrical insulation performance. This makes it well-suited for electrical equipment housings, insulating components and environments requiring safe, moisture-free insulation.

2. Applications

Industrial & Engineering

- Wear and impact components: Coal bunker liners, chute liners, conveyor slide plates, silo liners, guide rails, and impact pads.

- Chemical plant equipment: Corrosion-resistant plates, tank covers, pump/valve protective panels, chemical storage liners.

- Mechanical fabrication: Cutting boards, sliding blocks, profiles, and CNC-machined components.

Infrastructure & Utilities

- Wastewater treatment tanks, water supply components, gas pipelines, and industrial fluid handling systems (similar advantages to HDPE100 pipe).

- Long service life up to 50 years under –20°C to 65°C operating conditions.

- Non-scaling, hygienic, resistant to chemical media, lightweight and easy to install.

Food, Medical & Consumer Goods

- Food-grade work surfaces & trays: Non-toxic, odorless, hygienic, easy to clean.

- Medical components: Panels, structural parts and equipment housings where safety and corrosion resistance are required.

3. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material Grade | Virgin PE100 (high-strength HDPE) | Higher strength and long-term creep resistance than standard HDPE |

| Thickness | 3 – 40 mm (customizable) | Special thicknesses available on request |

| Width | 1000 – 2400 mm | Wide-format panels available |

| Length | Custom size | Cut-to-size & custom lengths supported |

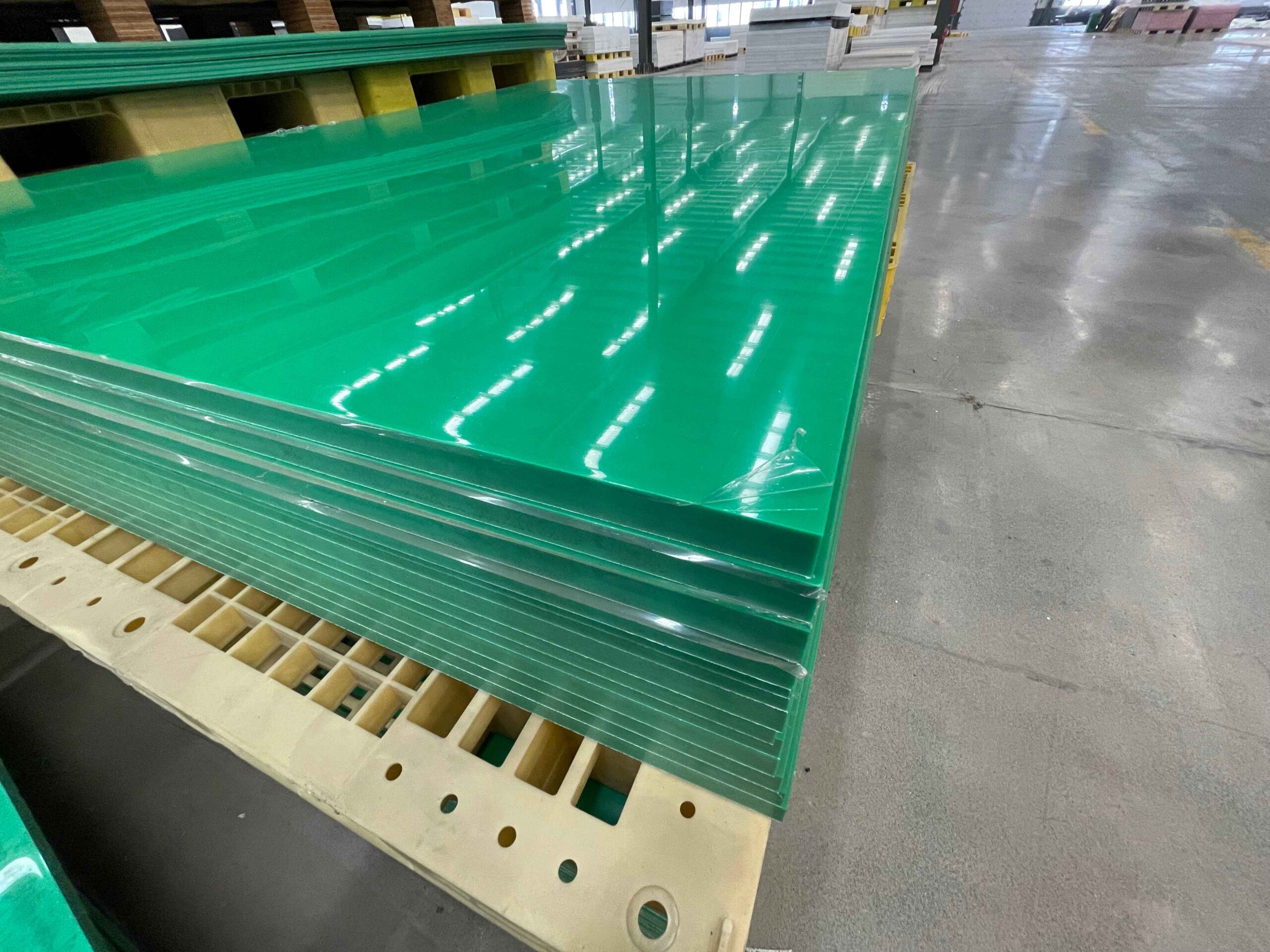

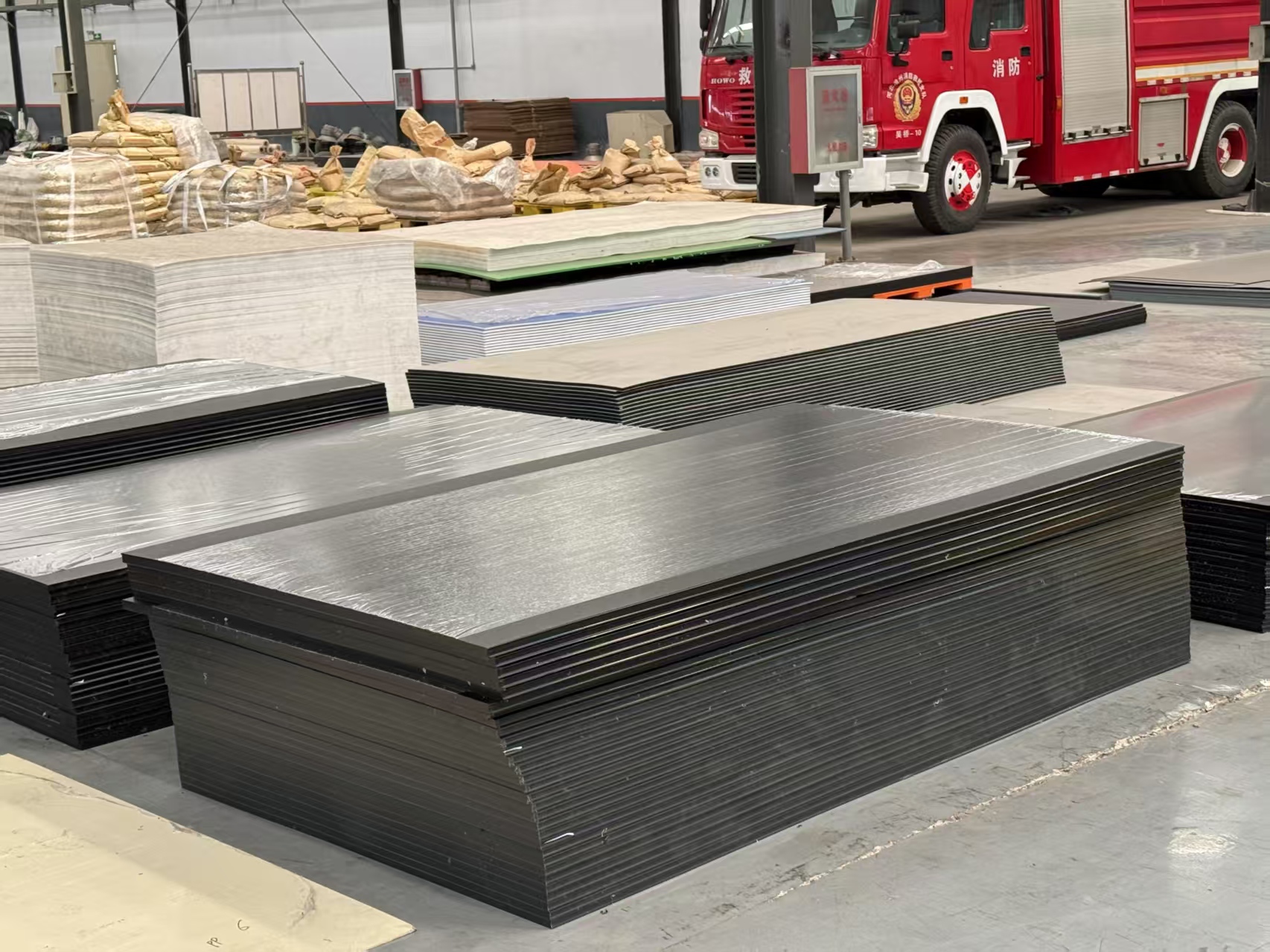

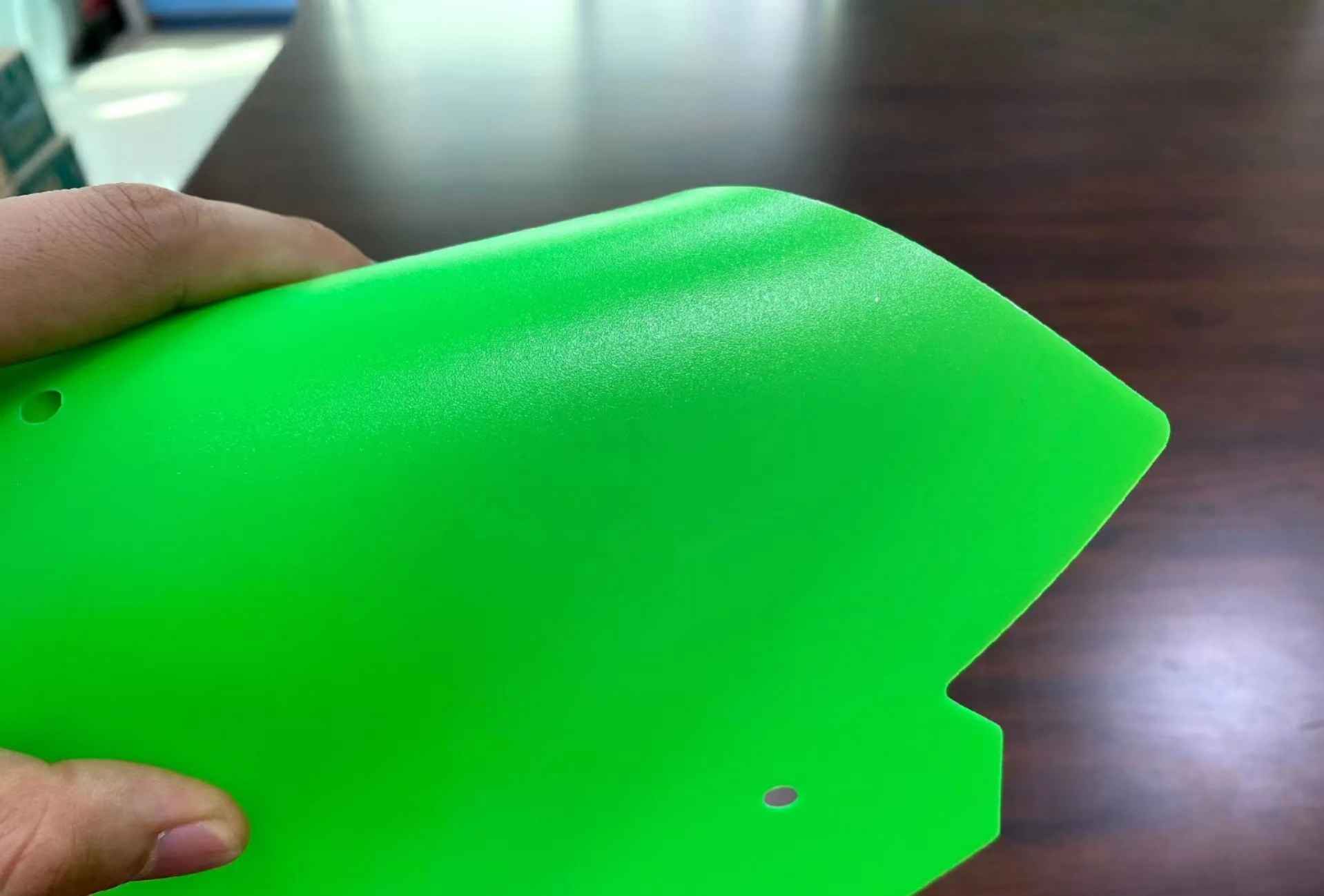

| Color | Natural white, black, grey, blue, green, yellow (custom colors available) | Color coding for industrial areas/branding |

| Surface Finish | Smooth / matte / textured / embossed | Anti-slip surface available |

| Chemical Resistance | Most acids, alkalis, salts, detergents | Not suitable for oxidizing acids |

| Moisture Absorption | Very low | Stable in wet/humid environments |

| Temperature Range | –70°C to +80°C | Excellent low-temperature impact resistance |

| Fabrication Options | Cutting, CNC machining, routing, welding | Supports custom shapes and components |

| Main Industries | Engineering, chemical, food, medical, machinery, mining, utilities | One board type for multiple sectors |

If you require HDPE100 Grade Boards for your project, please provide the application, thickness, size, color, quantity, and any drawings. We will recommend a suitable grade and deliver a customized solution with machining and fabrication services.