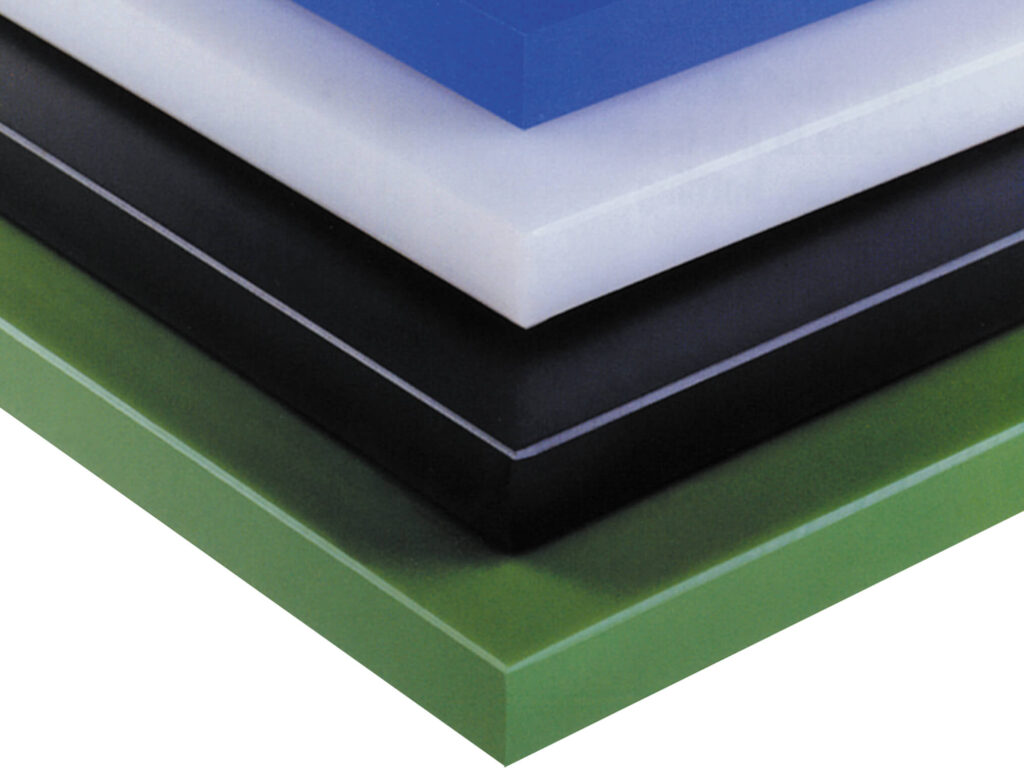

Cangzhou Shengliang Plastic Products Co., Ltd., established in 2018 in Wuqiao County, Hebei Province, China, specializes in producing high-performance engineering plastics like ultra-high molecular weight polyethylene (UHMWPE) sheets and nylon sheets. With an 18,000-square-meter facility equipped with extrusion machines, imported bending and welding tools, and gantry mills, the company offers factory-direct supply of custom-cut sheets for industries including chemicals, environmental protection, pharmaceuticals, metallurgy, and petroleum. These materials provide low-friction surfaces, high impact strength, and chemical resistance, enabling efficient fabrication into components like storage tanks, separators, and liners.

Ultra-High Molecular Weight Polyethylene (UHMWPE) Sheets: Core Properties and Applications

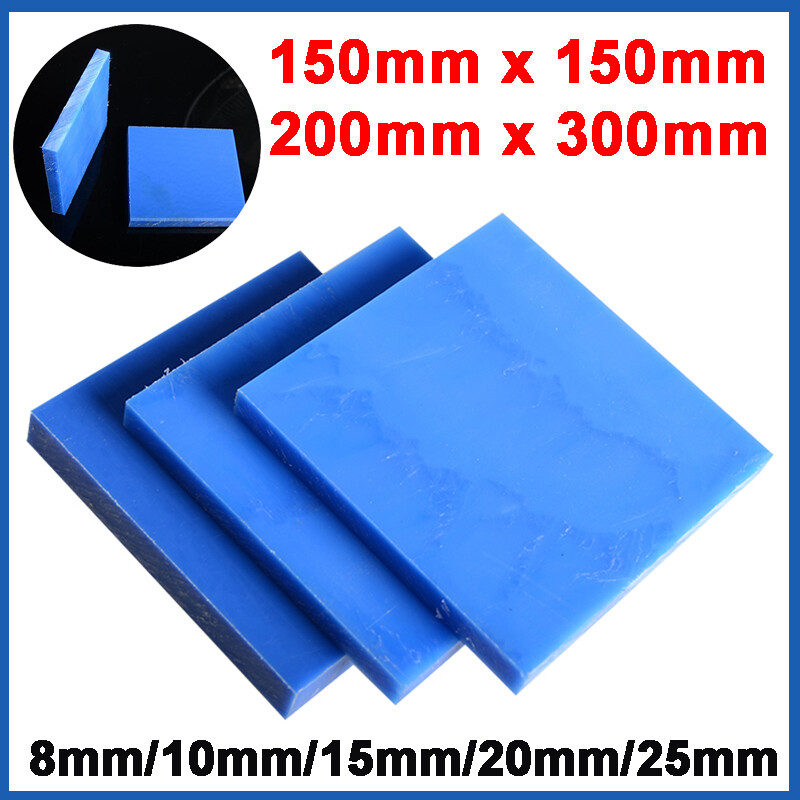

UHMWPE, often referred to as PE 1000, features a molecular weight exceeding 3 million g/mol, delivering exceptional abrasion resistance—up to 10 times that of carbon steel in sliding applications—and a coefficient of friction as low as 0.07-0.11, making it inherently self-lubricating without needing additional oils or greases. Its impact strength reaches 200 kJ/m² under notched Izod tests, outperforming most engineering plastics in cryogenic conditions down to -200°C. Density ranges from 0.93-0.96 g/cm³, ensuring lightweight yet durable performance, with no moisture absorption (less than 0.01%) and broad chemical resistance to acids, alkalis, and solvents.

In industrial settings, UHMWPE sheets serve as liners for hoppers and chutes in mining and bulk material handling, reducing sticking and wear while extending equipment life by 20-30% in abrasive environments like coal or ore processing. For conveyor systems, they form guide rails and wear strips, minimizing noise by up to 50 dB and energy consumption due to low friction. Biomedical applications include orthopedic implants, where its biocompatibility and ductility support over 1 million cycles in joint replacements without degradation. Shengliang processes these sheets into custom equipment like three-phase separators and spray towers, with thicknesses from 5-200 mm and sizes up to 4x8 feet, ensuring precise fits via CNC machining and welding.

Self-lubricating impact-resistant PE boards, typically UHMWPE variants, enhance these traits with additives like molybdenum disulfide for even lower friction (down to 0.05), suited for heavy-duty slides in synthetic ice rinks or flame-retardant insulation panels that withstand temperatures up to 80°C continuous. In coal bins, these boards prevent bridging, improving flow rates by 15-25% while resisting impacts from falling materials. Shengliang's direct supply ensures cost savings of 10-20% compared to intermediaries, with recyclable options meeting environmental standards.

Nylon Sheets: Engineering Performance and Uses

Nylon sheets, primarily PA6 or PA66 types, exhibit tensile strengths of 60-80 MPa, elongation at break up to 200%, and fatigue resistance allowing 10^6 cycles under alternating loads. They absorb up to 8% moisture, which enhances toughness but requires consideration in humid environments; however, this yields excellent damping, reducing vibrations by 30-50% in mechanical assemblies. With a melting point of 220-260°C and low friction (0.2-0.4), nylon offers good sliding properties, especially in filled grades with glass fibers boosting stiffness to 10 GPa.

Common applications include gears and rollers in automotive transmissions, where nylon's wear resistance extends part life by 2-3 times over metals, and bushings in machinery that eliminate the need for lubrication, cutting maintenance costs by 40%. In electrical engineering, they form insulators and seals due to dielectric strength of 20-30 kV/mm. Shengliang fabricates nylon sheets into custom parts like acid washing tanks, available in thicknesses of 8-25 mm and colors like blue or white, using imported tools for precise engraving and milling.

By sourcing directly from Shengliang, clients benefit from rapid turnaround—custom orders processed in 7-14 days—and compliance with ISO standards, ensuring reliable performance in demanding sectors. Contact via their website for quotes on specific dimensions or formulations.