1. What Is HDPE Sheet?

HDPE sheet is made from high density polyethylene resin by extrusion or pressing. The material combines good stiffness with high impact resistance and excellent chemical stability. Compared with metal or many other plastics, HDPE is lighter, does not rust and is easy to process into custom parts.

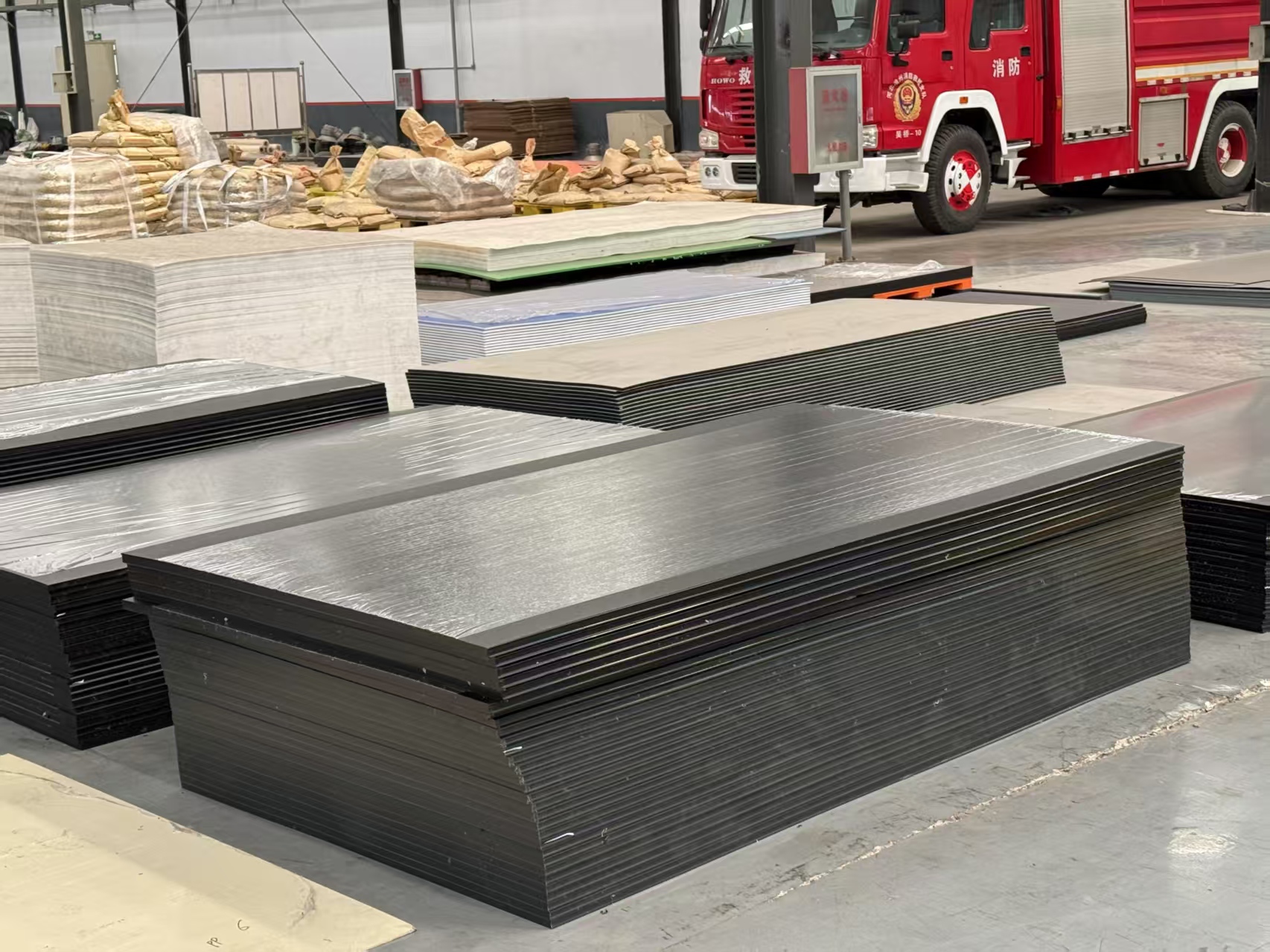

4. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material | High Density Polyethylene (HDPE) | Different HDPE grades available according to application |

| Thickness | Approx. thin sheets to thick plates | Exact thickness selected according to design and load |

| Sheet Size | Standard sheet sizes and custom cut-to-size | Cutting service according to your drawings |

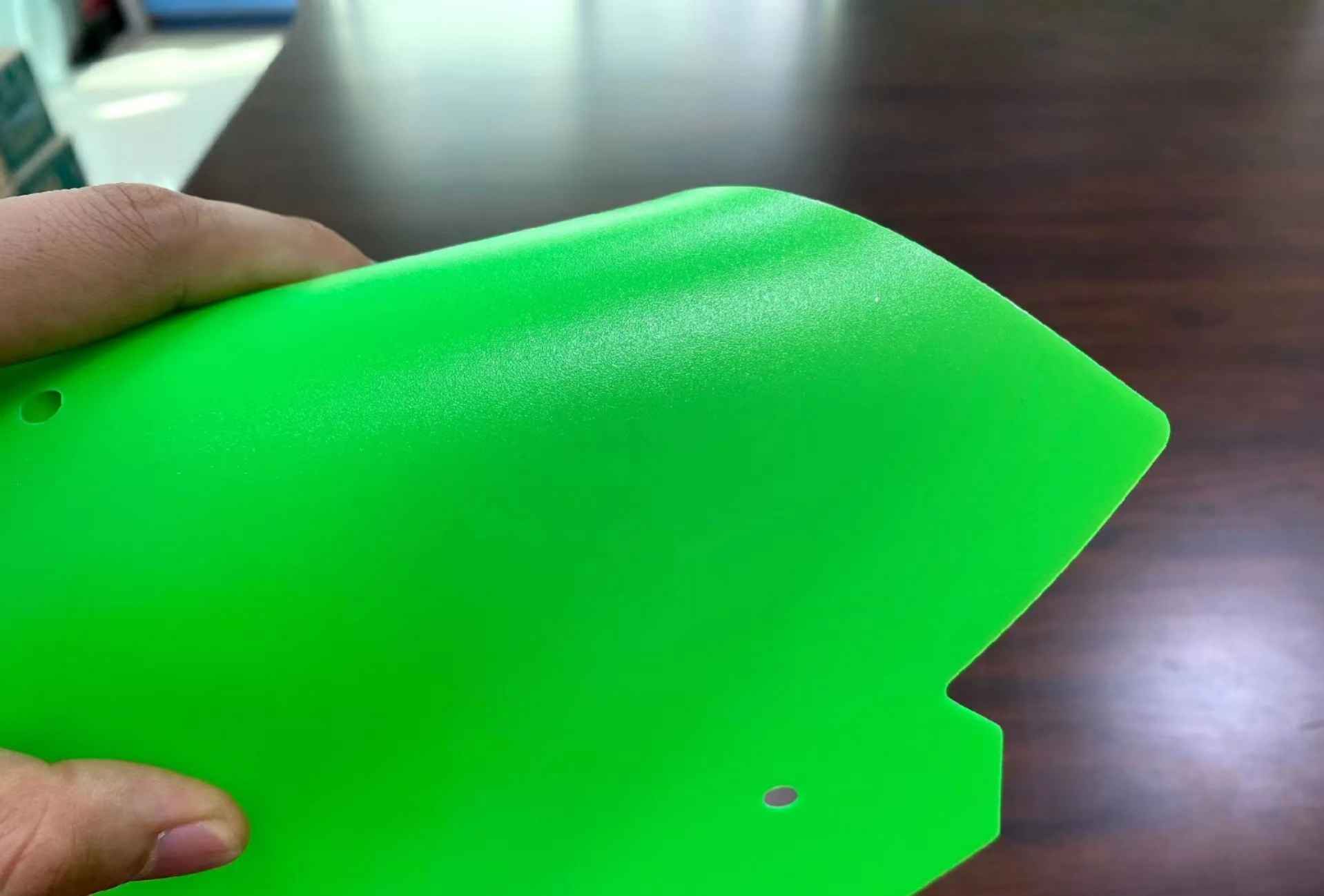

| Color | Natural, black and other colors on request | Color can be chosen for appearance or media identification |

| Density | Typical HDPE density | Lighter than many other solid materials |

| Surface Finish | Smooth, matte or light texture | Finish selected according to application needs |

| Chemical Resistance | Many acids, alkalis and salts | Compatibility should be checked for special media |

| Working Temperature | Typical HDPE operating range | Final limit depends on load, medium and safety factor |

| Processing Methods | Cutting, drilling, machining, welding, forming | Suitable for CNC machining and plastic welding |

| Main Industries | Chemical, water treatment, machinery, conveying, food-adjacent | One material for many industrial applications |

For HDPE sheets, please provide your required thickness, sheet size or cutting dimensions, color, quantity and application details. We will help you choose suitable specifications and offer cutting, machining and fabrication services according to your drawings.

- Material: High density polyethylene (HDPE).

- Form: Flat sheets and plates in different thicknesses, colors and sizes.

- Processing: Cutting, drilling, milling, turning, routing and plastic welding.

2. Key Properties of HDPE Sheet

Mechanical Properties

- High impact strength: Resists impact and shock without brittle failure, even at low temperatures.

- Good stiffness with flexibility: Offers enough rigidity for structural use while maintaining some flexibility to absorb stress.

- Low friction surface: Naturally slippery, suitable for sliding parts, liners and conveying components.

Chemical & Environmental Performance

- Chemical resistance: Resistant to many acids, alkalis and salt solutions used in water treatment, chemical and industrial processes.

- Low water absorption: Very low moisture uptake, keeping dimensional stability in wet or immersed service.

- No rust or rot: Unlike metal or wood, HDPE does not rust, rot or support mildew growth.

Processing & Hygiene

- Easy to machine: Can be cut and machined with woodworking or plastic tools; suitable for CNC machining.

- Good weldability: Hot-air and extrusion welding can be used to fabricate tanks, boxes and structural assemblies.

- Easy to clean: Smooth, non-porous surface is easy to wash and maintain.

3. Typical Applications of HDPE Sheet

- Liners and protection: Chute liners, silo and hopper liners, truck bed liners, wear plates and anti-impact panels.

- Water & wastewater: Components and liners in tanks, channels, equalization tanks and treatment units.

- Machined parts: Blocks, guides, spacers, sliding parts and general mechanical components.

- Cutting boards and food-adjacent uses: HDPE is commonly used as cutting boards and work surfaces in food-related environments (grade depending on local regulations).

- General industrial panels: Machine guards, covers, partitions and light structural panels.