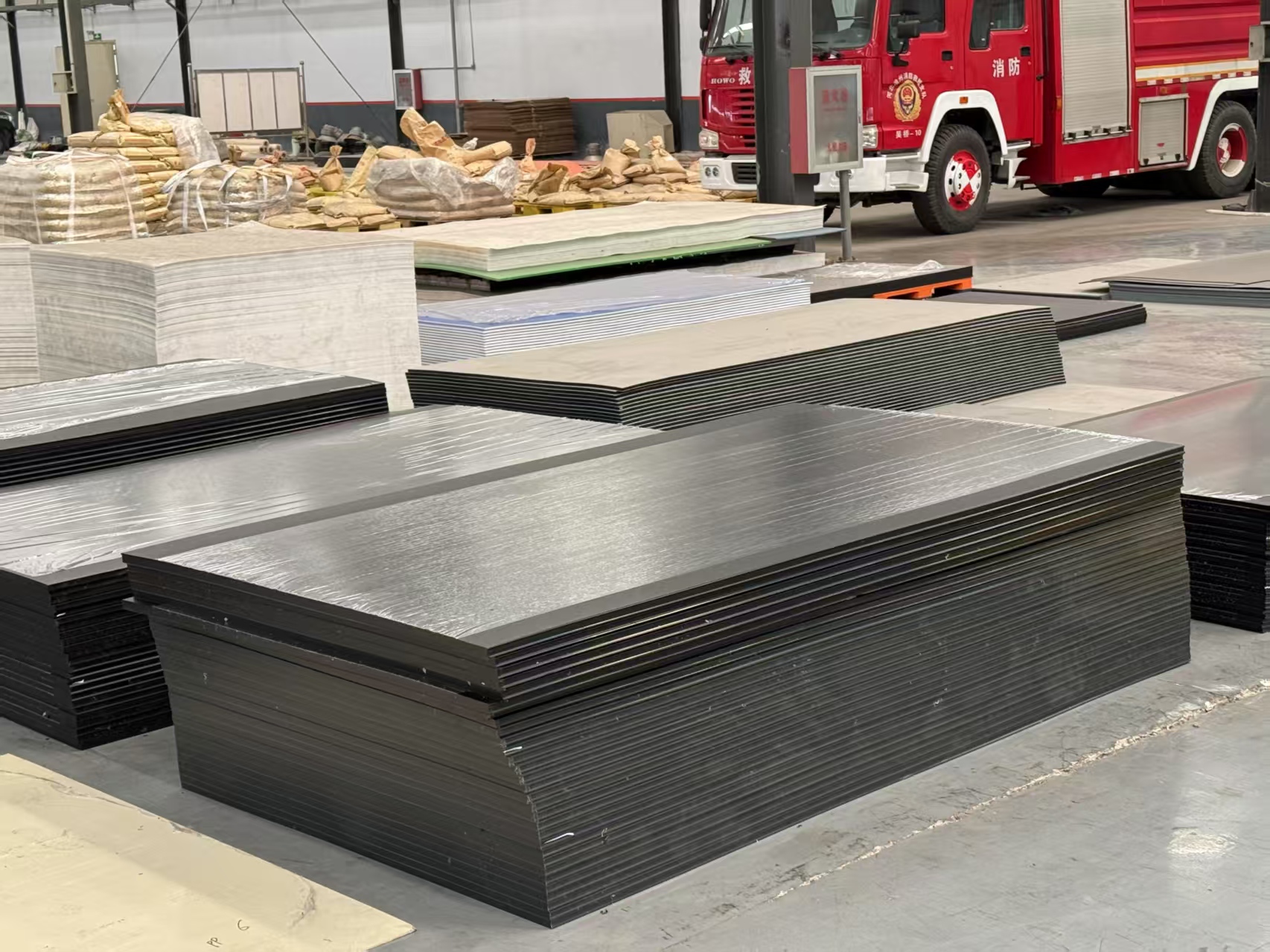

HDPE Textured Sheet is a high-density polyethylene board with an embossed, frosted or patterned surface. It combines the chemical resistance, impact strength and low water absorption of HDPE with a functional textured finish that improves grip, hides scratches and enhances appearance. It is widely used in architectural cladding, hygienic wall panels, industrial linings, vehicle and equipment interiors, and other decorative or protective applications.

- Durable and dimensionally stable: Good rigidity and toughness, with stable size under normal temperature changes for indoor and outdoor use.

- Chemical- and moisture-resistant: Resistant to many acids, alkalis, salts and moisture, suitable for corrosive or humid environments such as chemical plants and food processing areas.

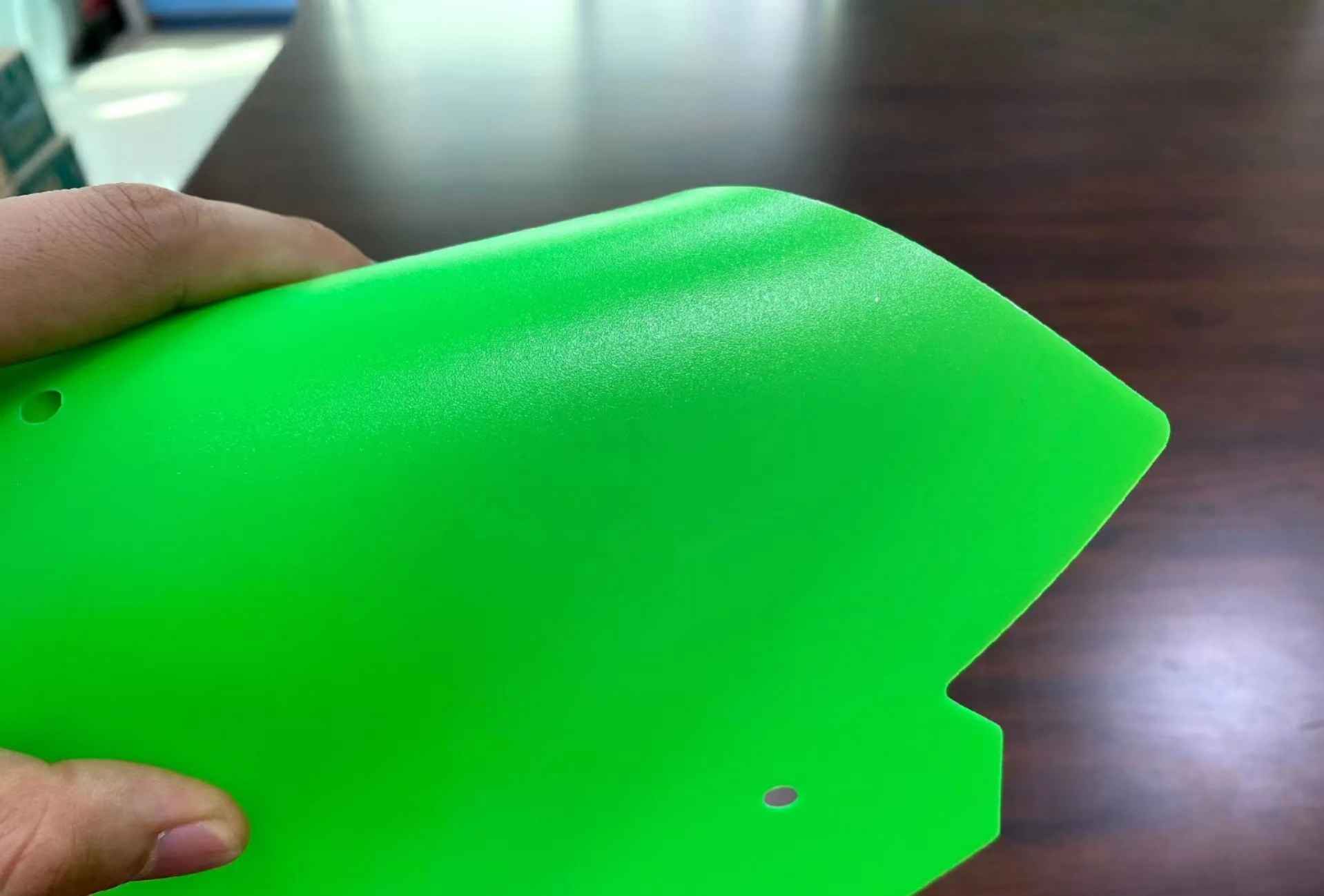

- Textured surface for function and aesthetics: Embossed or frosted finishes improve anti-slip performance, hide everyday scratches and offer a refined decorative effect.

- Hygienic and easy to clean: Low water absorption, mold- and fungi-resistant surface, ideal for food, medical and cleanroom-type environments.

- Rich colors and customization: Available in a variety of colors, thicknesses and sheet sizes; textures and colors can be customized to match design concepts or brand identity.

Typical Specifications of HDPE Textured Sheet

| Item | Typical Value / Range | Notes |

|---|---|---|

| Material | High-Density Polyethylene (HDPE) | Virgin HDPE or specified grade on request |

| Density | Approx. 0.94 – 0.97 g/cm³ | Lighter than metal, easy to handle and install |

| Standard Thickness | Approx. 3 – 30 mm | Other thicknesses can be customized |

| Standard Sheet Size | 1220 × 2440 mm (4' × 8') or custom | Max. width up to around 1.6 m; length can be cut to order |

| Color Options | White, black, grey, blue, green, yellow, red, etc. | Single-color, dual-color or custom color according to color code |

| Surface Texture | Embossed, frosted, matt or other textures | Anti-slip or decorative textures available depending on application |

| Water Absorption | Very low | Helps maintain dimensional stability in humid environments |

| UV & Weather Resistance | Good, especially with UV-stabilized grades | Suitable for many outdoor decorative and structural uses |

| Chemical Resistance | Resistant to many acids, alkalis and salts | Commonly used in chemical, food and industrial environments |

| Typical Applications | Wall and ceiling panels, cladding, hygienic wall lining, equipment and vehicle interiors, industrial linings | Used in buildings, food plants, medical facilities, machinery and more |

| Processing Methods | Cutting, drilling, routing, CNC machining, thermoforming | Can be fabricated into custom panels and components according to drawings |

If you need HDPE Textured Sheets with specific color, texture, thickness or sheet size, please send us your drawings or design requirements. Our team can recommend suitable specifications according to your application (indoor/outdoor, decorative/industrial, food/medical) and provide a competitive quotation.