1. Product Overview

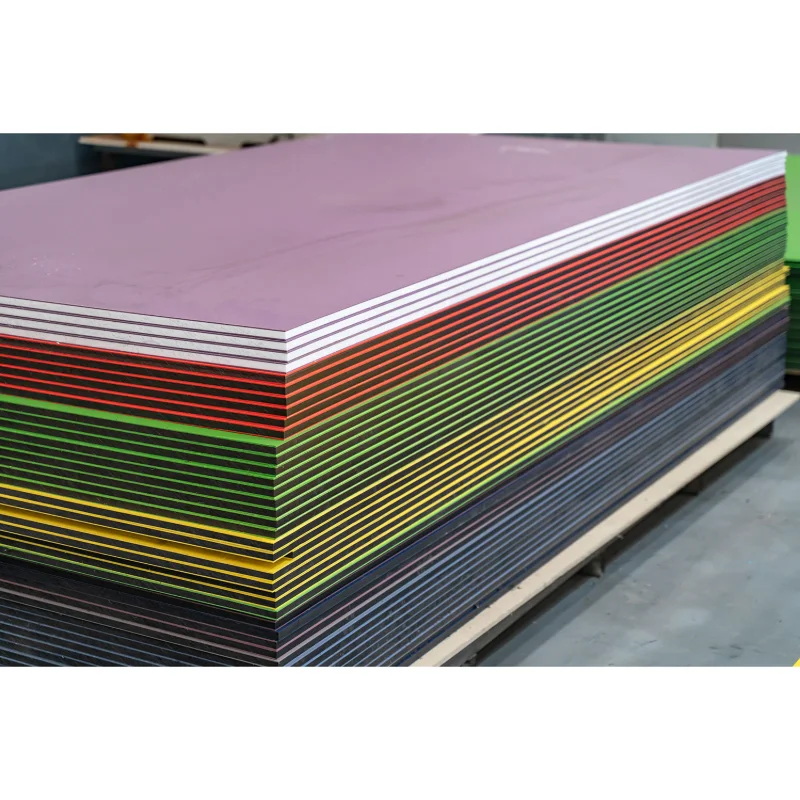

HDPE two-color sheets are produced by co-extruding different colored HDPE layers into a single, homogeneous sheet. The thin surface layer has one color, while the inner core has a contrasting color. When the surface is engraved or routed, the inner color is exposed to form clear, permanent patterns, letters and graphics.

- Material: High-density polyethylene (HDPE), environmentally stabilized for outdoor use.

- Structure: Multi-layer sheet with contrasting cap and core colors, typically symmetrical (cap–core–cap).

- Finish: Commonly matte or lightly textured on both sides to reduce glare and hide scratches.

2. Key Features

Durability & Weather Resistance

- UV-stabilized: Designed for outdoor use; color and mechanical properties remain stable under sunlight.

- Waterproof and rot-proof: Will not absorb water, warp, delaminate or rot in wet or marine environments.

- Abrasion and impact resistance: HDPE base material resists impact, scratching and everyday abuse in playground and public environments.

Engravable Two-Color Design

- High contrast graphics: Engraving or routing through the cap layer reveals the core color, producing clear text and symbols without painting.

- Long-lasting appearance: Color runs through each layer; graphics will not peel or flake like printed or laminated surfaces.

- Double-sided use: Many designs can be used from both sides, offering flexibility in sign and panel layout.

Processing & Machining

- Easy to process: Can be cut, drilled, routed and engraved using standard woodworking or plastic-machining equipment.

- Chip-forming machining: Produces chips rather than dust, making workshop handling and cleaning easier.

- Thermoplastic behavior: Can be heat-formed or bent within HDPE’s normal processing range for special shapes.

3. Typical Applications

- Signage & wayfinding: Outdoor building signs, information boards, safety signs, direction signs and industrial labels.

- Playground & recreation: Panels for playground equipment, decorative inserts, activity boards and safety boards.

- Marine & waterfront: Name plates, control panels, decorative panels and information signs on boats, docks and marinas.

- Architectural & landscape: Decorative panels, façade accents, park signs, trail markers and feature boards.

- Branding panels: Corporate logos, themed graphics and long-lasting branded elements for outdoor installations.

4. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material | High-density polyethylene (HDPE) | Outdoor-grade, UV-stabilized material available |

| Structure | Cap–core–cap multi-layer sheet | Contrasting surface color and core color |

| Thickness | Commonly around 6 – 20 mm | Other thicknesses available on request |

| Standard Sizes | Typical sheets similar to 1220 × 2440 mm (4 × 8 ft) | Custom cut-to-size service available |

| Cap/Core Color Combinations | e.g. black/white, blue/white, green/yellow, red/yellow | Custom color combinations can be matched for projects |

| Surface Finish | Matte or textured surface | Helps hide fingerprints and minor scratches |

| Density | Typical HDPE density | Lightweight compared with many solid materials |

| Weather Resistance | Suitable for outdoor use | Will not rust, rot or delaminate in normal conditions |

| Processing | Cutting, drilling, CNC routing, engraving, limited thermoforming | Compatible with common woodworking/plastic tools |

| Main Application Fields | Signage, playground, marine, architecture, branding | One sheet solution for outdoor decorative and information panels |

For HDPE two-color sheets used in signage, playgrounds, marine or architectural projects, please provide your application, color combination, thickness, sheet size, machining drawings and quantity. We can help you choose suitable material specifications and offer value-added services such as cutting, engraving and edge finishing.