To meet the growing demand for high-performance polypropylene (PP) sheets, manufacturers are continuously exploring ways to enhance their physical and mechanical properties. From optimizing raw materials to upgrading production lines, several approaches can significantly boost the performance and reliability of PP sheets across various applications.

1. Enhancing Material Properties with Additives

One effective way to improve PP sheet performance is by adding chemical fibers or modifying agents during the production process. This can significantly improve strength, flexibility, and especially elongation performance, which is crucial for applications like metal stamping or gasket production.

Some manufacturers also blend high-pressure polyethylene (HDPE) with PP to enhance its physical properties, such as impact resistance and toughness.

Because PP has a relatively high melting point and is a semi-crystalline material, it already offers strong economic and performance advantages. But for more demanding or specialized applications, further improvements in material formulation are essential.

2. Optimizing Production Technology

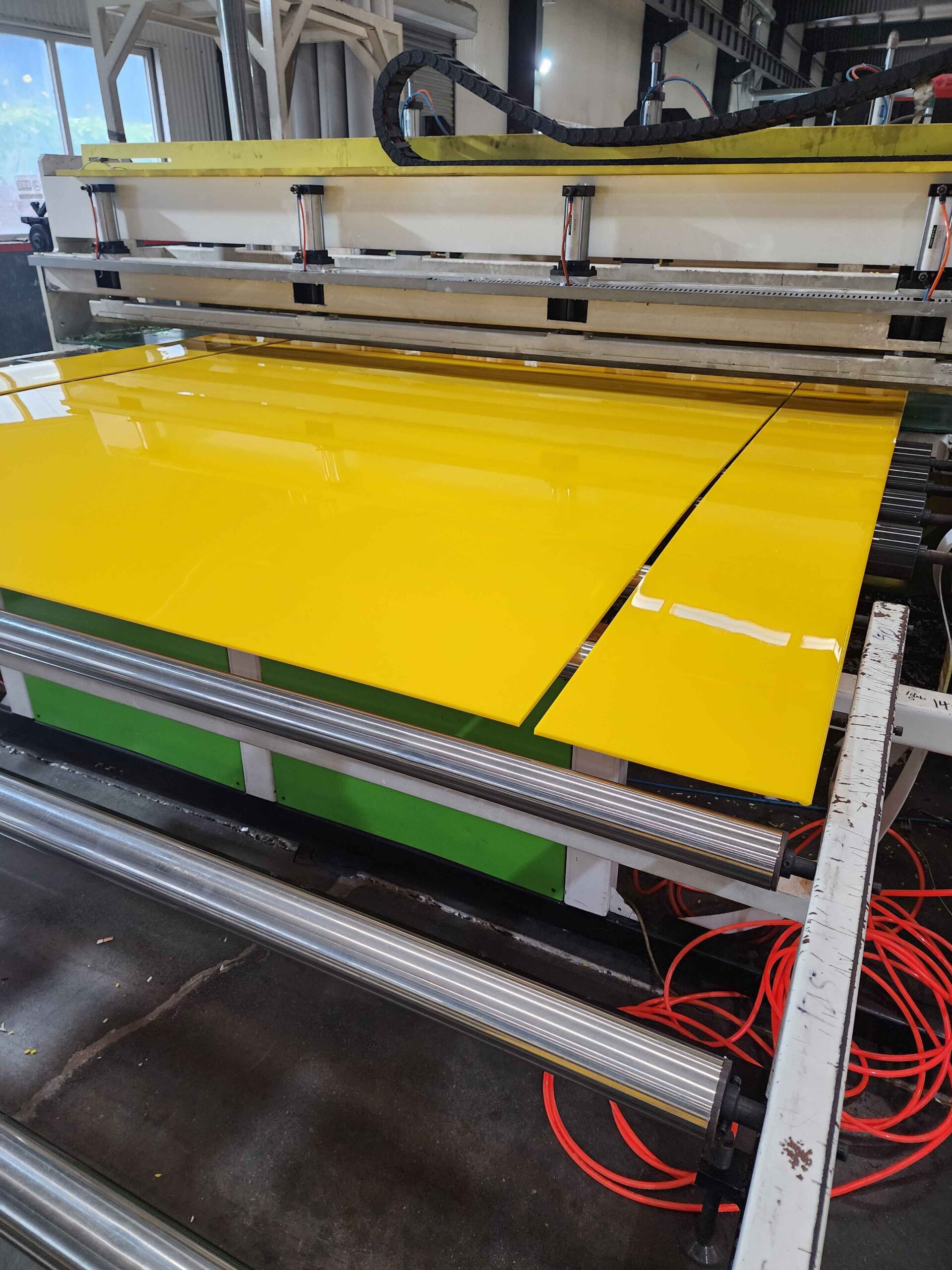

High-quality PP sheet production requires an advanced extrusion line with precise process control. Key features of a modern PP sheet extrusion line include:

- Screw design based on PP-R rheology: This ensures strong melt capacity, excellent dispersion, and uniform melt temperature, all of which are essential for consistent quality.

- Accurate speed ratio and bolt structure: These features support better control over melt flow and enable smoother processing.

- Optimized residence time: In both the extruder and die head, the PP-R melt must have the correct dwell time to avoid oxidative degradation caused by excessive heating.

- Integrated strip-coating system: Some lines offer inline marking or strip-coating during sheet extrusion, which helps with traceability and identification.

Additionally, using DC variable frequency-controlled extruders (e.g., 30mm screw diameter) ensures efficient, compact, and user-friendly operation—something that customers appreciate.

3. Advanced Material Formulation

High-performance PP sheets are often made using imported-grade materials and enhanced with additives like:

- UV stabilizers

- Anti-aging agents

- Stress-relief technology to prevent warping, bubbling, or cracking

These improvements extend the lifespan of the sheet, prevent discoloration, and enhance structural integrity.

4. Customization Options

PP sheets come in various colors and sizes to meet different industry needs. Common color options include:

- Natural white (milky white)

- Light grey

- Porcelain white

Sizes (customizable):

- Thickness: 3mm – 200mm

- Standard sizes: 1000mm x 2000mm, 1220mm x 2440mm, 1500mm x 3000mm, etc.

5. Key Features of PP Sheets

- Low density and lightweight

- High thermal resistance, non-deforming

- Excellent rigidity and surface hardness

- Stable chemical properties

- Strong electrical insulation

- Non-toxic and environmentally safe

- Smooth, glossy surface

- Easy to fabricate and weld

- Long service life and easy maintenance

6. Applications of PP Sheets

Thanks to their durability, chemical resistance, and ease of fabrication, PP sheets are used in a wide range of industries, including:

- Drinking water and drainage piping systems

- Hydraulic seals and spray systems

- Corrosion-resistant tanks and containers

- Chemical processing and wastewater treatment equipment

- Air purification and exhaust gas systems

- Cleanrooms and semiconductor manufacturing

- Food-grade machinery and cutting boards

- Electroplating and surface treatment industries

Conclusion:

To stay competitive, PP sheet manufacturers must combine material innovation, advanced extrusion technology, and customization flexibility. By continuously improving performance, they can meet the evolving needs of both industrial and consumer markets.