Molecular Structure

Ultra-high molecular weight polyethylene (UHMWPE), a variant of polyethylene with a significantly higher molecular weight, shares a similar linear structure with low-density polyethylene (LDPE) and high-density polyethylene (HDPE). This linear structure, combined with its exceptionally high molecular weight, endows UHMWPE with superior properties compared to other plastics. These include excellent wear resistance, outstanding impact strength, corrosion resistance, and self-lubricating characteristics.

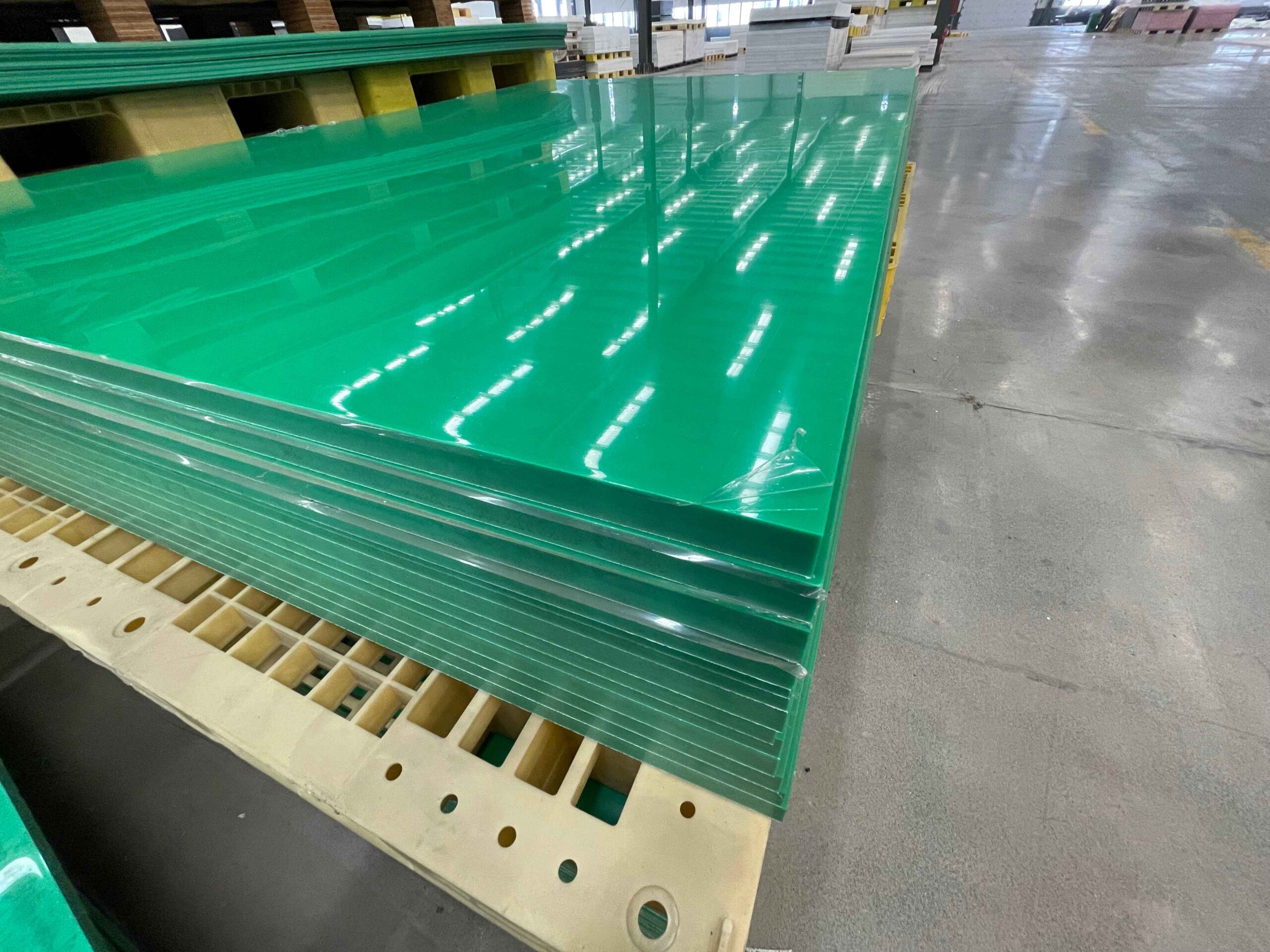

Role in Engineering Applications

With advancements in technology, engineering plastics like UHMWPE have become critical not only in everyday manufacturing and consumer products but also in cutting-edge fields. The remarkable properties of UHMWPE have garnered significant attention, leading to its widespread adoption across various industries. However, challenges such as difficulties in melt processing, low surface hardness after molding, and poor heat resistance have limited its broader application. Consequently, research has focused on improving processing techniques and optimizing performance to overcome these barriers.

Performance Enhancement through Modification

To enhance the performance of UHMWPE, composite materials are developed using a resin matrix modified with organic and inorganic nanofillers, processed via extrusion molding. Studies have investigated the effects of varying amounts of organic fillers and inorganic nanofillers on the composite’s heat resistance, mechanical properties, and surface hardness. Findings indicate that both types of fillers effectively improve heat resistance and surface hardness. However, they may compromise the mechanical properties of the composite. Specific formulations can be tailored to enhance mechanical strength, balancing the trade-offs to meet application-specific requirements.

Summary

The linear structure and high molecular weight of UHMWPE provide exceptional properties, making it a versatile material for diverse applications. While challenges in processing and performance persist, ongoing research into filler-modified composites aims to optimize its heat resistance, surface hardness, and mechanical properties, further expanding its potential in advanced engineering applications.