Product Overview

PP-A board is an extruded polypropylene sheet based on optimized PP formulations for chemical resistance and weldability. It keeps the typical advantages of polypropylene—low density, good stiffness and resistance to many chemicals—while emphasizing stable performance in continuous industrial service.

- Material type: Modified polypropylene (PP-A) designed for chemical and environmental equipment.

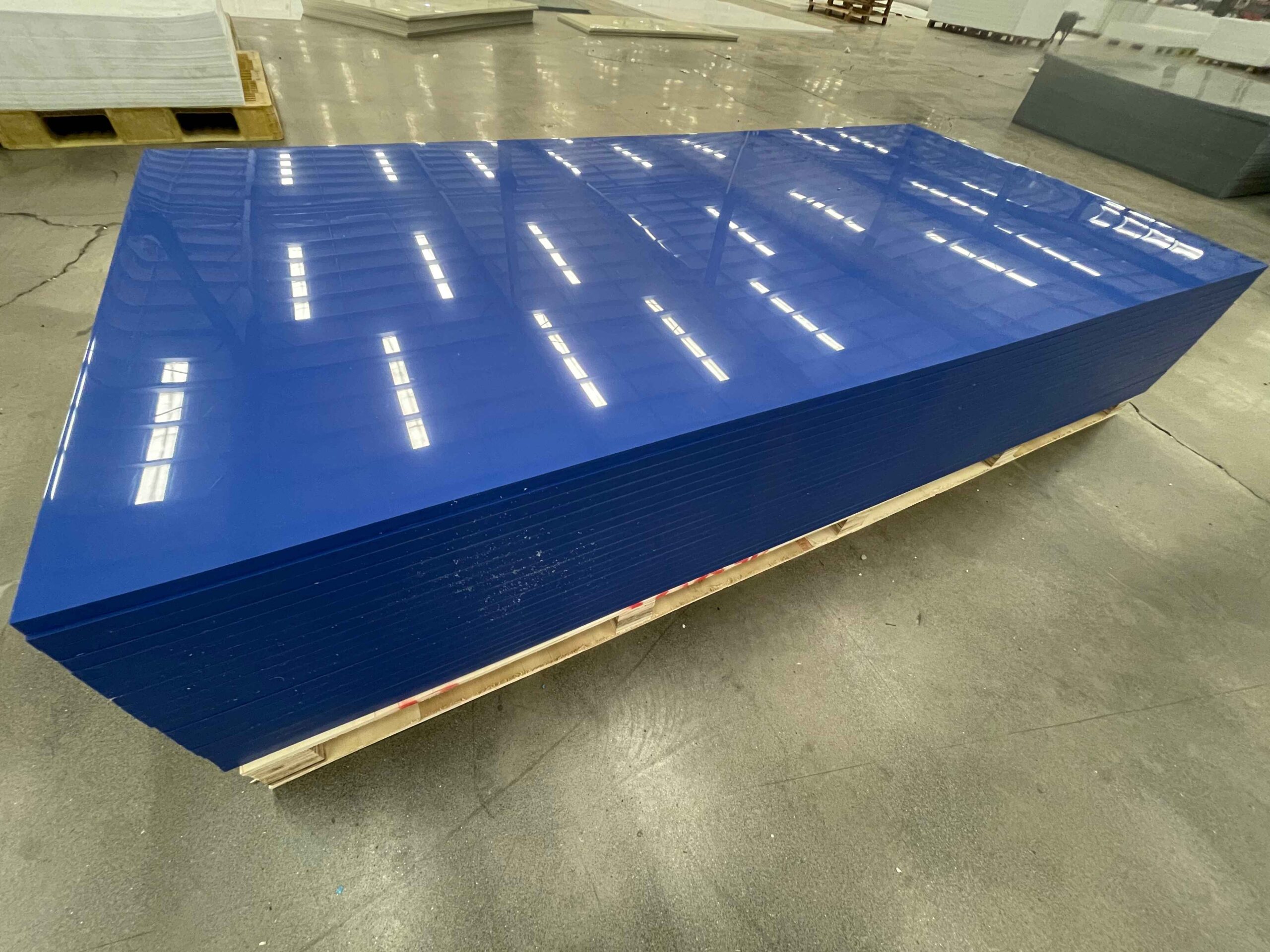

- Form: Flat boards with smooth or lightly textured surface, uniform thickness and good flatness.

- Processing: Suitable for cutting, welding and machining into finished components or complete equipment.

2. Key Features of PP-A Board

Chemical & Environmental Resistance

- Corrosion resistance: Suitable for many inorganic acids, alkalis and salts used in pickling, plating, exhaust-gas treatment and wastewater systems.

- Stable in humid and wet conditions: Very low water absorption and good resistance to moisture and splash environments.

- No metal corrosion: Will not rust or introduce metal ions into the process medium, helping maintain fluid purity.

Mechanical & Physical Properties

- Low density: Much lighter than steel and many other materials, reducing structural loads and simplifying installation.

- Good stiffness and strength: Suitable for tank walls, panels, ducting and structural parts when properly supported.

- Impact resistance: Adequate toughness for industrial use as guards, covers and equipment panels.

Processing & Fabrication

- Excellent weldability: Compatible with hot-air and butt welding for assembling tanks, scrubbers, ducts and custom equipment.

- Easy machining: Can be cut, drilled, routed and CNC machined using common plastic fabrication tools.

- Clean surface: Smooth, easy-to-clean surface simplifies maintenance and inspection.

3. Typical Applications

- Chemical equipment: Tanks, reaction vessels, plating and pickling lines, chemical scrubbers and absorption towers.

- Exhaust & ventilation systems: Corrosion-resistant exhaust ducts, fume hoods, elbows, plenums and ventilation boxes.

- Wastewater & environmental projects: Structurally robust panels and linings for treatment tanks, channels, covers and treatment equipment.

- Surface treatment & electronics: Etching, cleaning and treatment tanks in PCB and surface-treatment lines.

- General industrial equipment: Machine guards, splash shields, equipment covers and structural panels requiring chemical resistance.

4. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material | PP-A (modified polypropylene) | Formulated for chemical equipment and environmental systems |

| Thickness | Approx. 3 – 40 mm | Other thicknesses available on request |

| Width | Commonly 1000 – 2000 mm | Max. width depends on extrusion capability |

| Length | Standard sheet lengths or custom cut-to-size | Optimized cutting per your drawings |

| Color | Grey, natural or custom colors | Color coding for process zones and media |

| Surface Finish | Smooth or lightly textured | Textured surface can help hide scratches |

| Chemical Resistance | Many acids, alkalis and salts | Confirm compatibility for strong oxidizing agents and special solvents |

| Water Absorption | Very low | Suitable for humid, splash and immersion environments |

| Service Temperature | Typical PP operating range | Exact limit depends on load, safety factor and project design |

| Fabrication Options | Cutting, drilling, CNC machining, hot-air welding, butt welding | Supports fabrication of complete equipment from drawings |

| Main Industries | Chemical, environmental, surface treatment, electronics, machinery | One corrosion-resistant sheet solution for multiple sectors |

For PP-A board used in chemical tanks, scrubbers, exhaust systems or wastewater projects, please share your medium, concentration, working temperature, thickness and size requirements, quantity and engineering drawings. We will recommend suitable PP-A specifications and provide machining, welding and fabrication services to support your project.