1. Product Overview

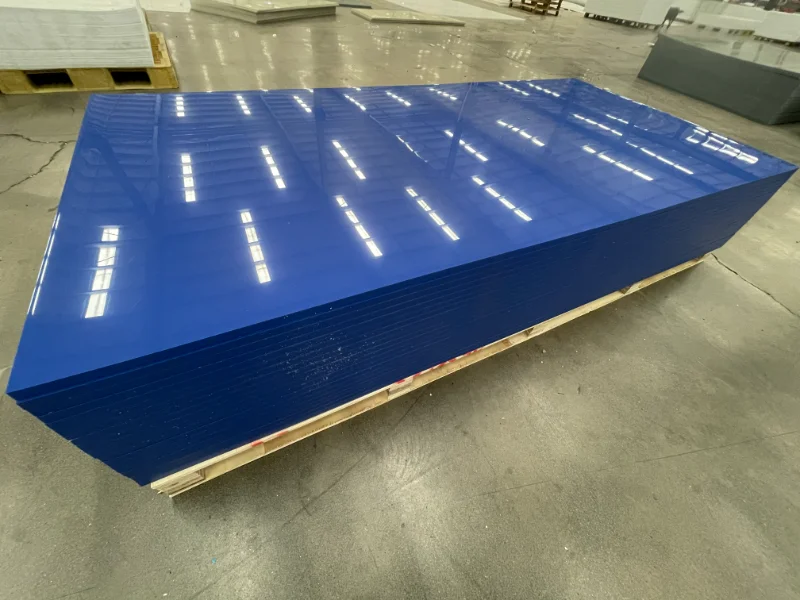

Fiber reinforced polypropylene (FRPP) board is produced by compounding polypropylene with fibers (often glass fibers) and then extruding into flat sheets. The fibers form a reinforcing skeleton inside the PP matrix, increasing the modulus and strength of the material while maintaining much of PP’s corrosion resistance and weldability. As a result, FRPP boards are widely used as structural panels and linings in chemical and environmental equipment.

- Composite design: PP matrix + fibers work together to provide higher stiffness and strength.

- Stable flat sheets: Good flatness and uniform thickness for reliable fabrication and assembly.

- Processability: Can be cut, drilled, machined and welded similar to conventional PP sheets.

2. Key Features

Mechanical & Structural Performance

- High stiffness: Reduced panel deflection under water pressure or wind load compared with standard PP boards.

- Higher strength: Improved load-bearing capability for tank walls, towers, ducts and large equipment shells.

- Better dimensional stability: Less creep and deformation under long-term load and elevated temperature.

Chemical & Environmental Resistance

- Corrosion resistance: Suitable for many inorganic acids, alkalis and salt solutions used in chemical processes and wastewater treatment.

- No rust or scaling: Unlike metals, FRPP does not corrode or introduce metal ions into the medium.

- Low water absorption: Maintains mechanical and dimensional properties in humid or immersed service.

Processing & Fabrication

- Thermoplastic weldability: Can be joined by hot-air welding, extrusion welding or butt welding to build complete equipment.

- Machinability: Standard plastic tools can be used for cutting, drilling, routing and CNC machining.

- Clean, maintainable surface: Smooth surfaces are easy to wipe down and inspect in operation.

3. Typical Applications

- Chemical storage and process tanks: Large rectangular or cylindrical tanks, scrubbers, absorber towers and washing towers.

- Exhaust gas and ventilation systems: Exhaust ducts, flues, elbows, plenums and housings in corrosive or humid conditions.

- Wastewater and environmental equipment: Structural panels and linings for treatment tanks, channels, covers and process units.

- Surface treatment and plating: Etching, pickling and plating tanks, overflow weirs and splash protection components.

- General industrial structures: Load-bearing panels, frames, guards and partitions in chemical or coastal environments.

4. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material | Fiber reinforced polypropylene (FRPP) | PP matrix with reinforcing fibers |

| Thickness | Approx. 5 – 40 mm | Thicker boards available for large tanks and towers |

| Width | Commonly 1000 – 2000 mm | Maximum width depends on extrusion line |

| Length | Standard sheet length or custom cut-to-size | Cutting layout can be optimized according to drawings |

| Color | Grey as standard; other colors on request | Color coding available for media or area identification |

| Surface Finish | Smooth or lightly textured | Textured finish can help hide scratches and wear |

| Chemical Resistance | Many inorganic acids, alkalis and salts | Compatibility should be checked for strong oxidizing media and special solvents |

| Water Absorption | Very low | Suitable for humid, splash and immersion environments |

| Service Temperature | Typical PP operating range | Actual limit depends on load, medium and design safety factor |

| Mechanical Performance | Higher stiffness and strength than standard PP sheets | Specific values depend on fiber type and content |

| Fabrication Options | Cutting, drilling, CNC machining, hot-air welding, butt welding | Supports fabrication of complete tanks, ducts and structural parts |

| Main Industries | Chemical, environmental, surface treatment, exhaust systems, machinery | Especially suited for large and load-bearing components |

For fiber reinforced polypropylene boards used in tanks, scrubbers, exhaust ducts or environmental systems, please provide your application details, medium and temperature, required thickness and size, strength expectations and engineering drawings. We will recommend suitable FRPP specifications and offer machining, welding and fabrication services for your project.