1. Product Overview

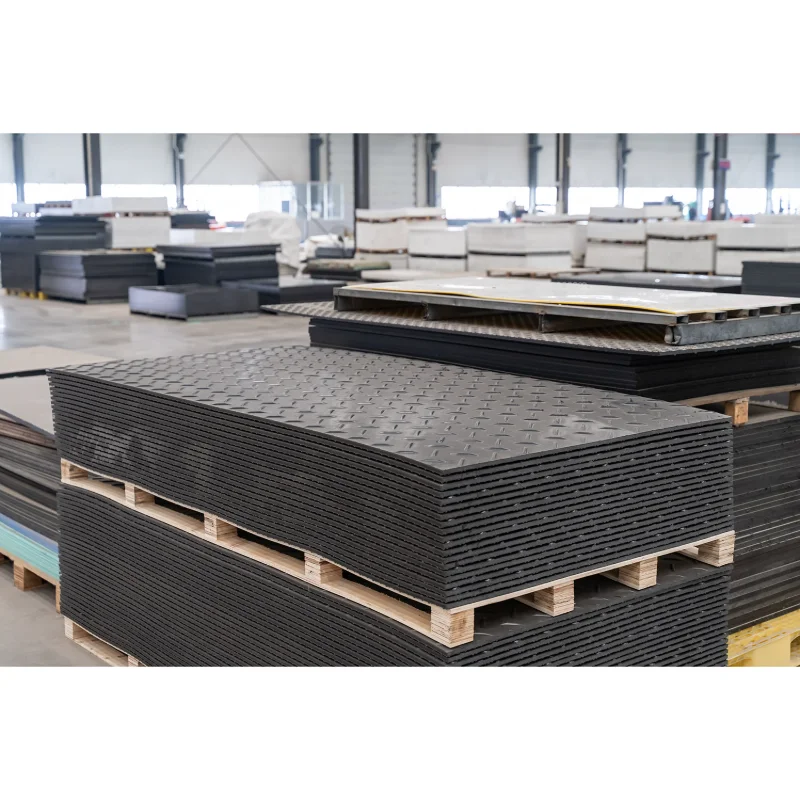

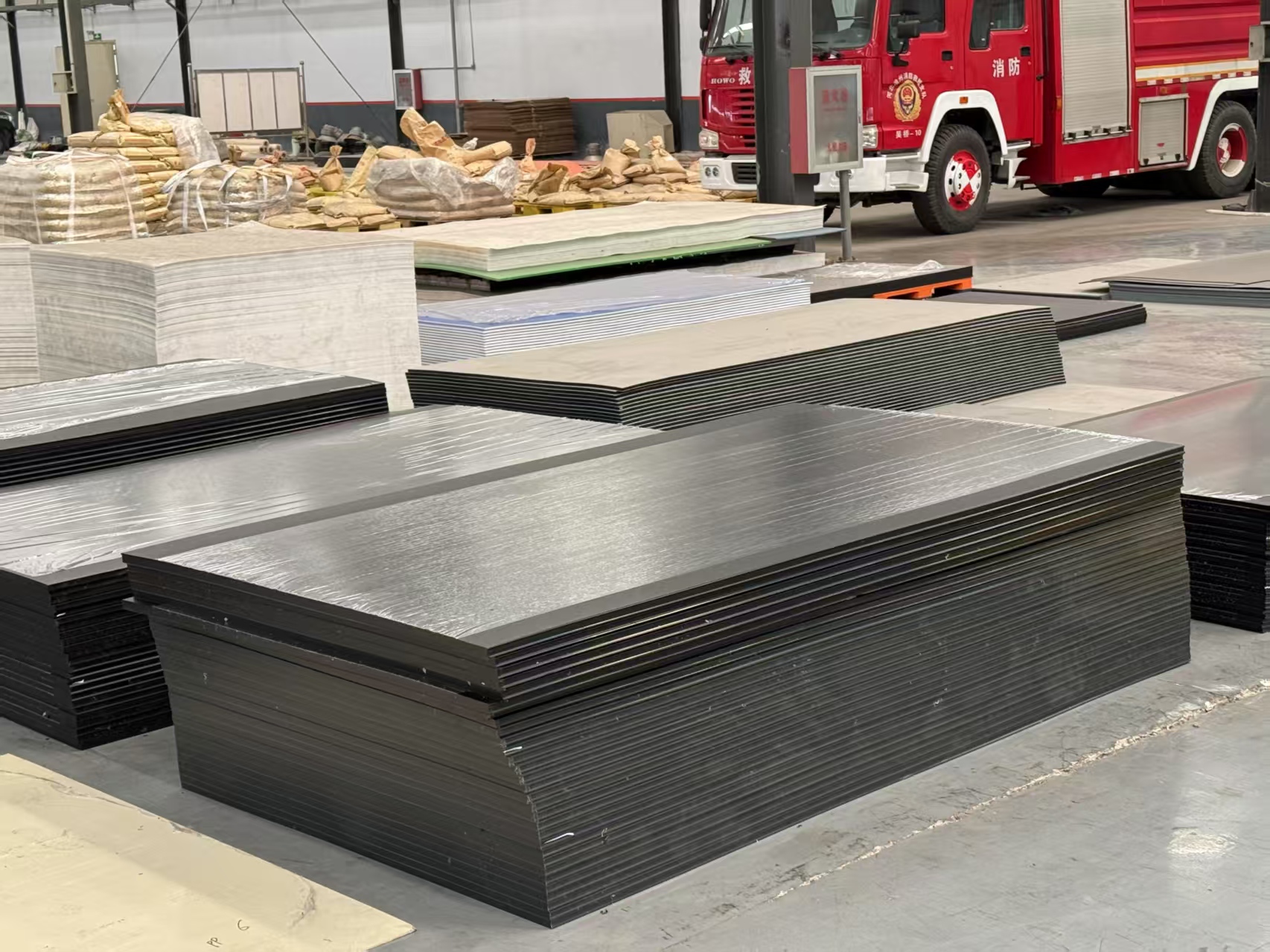

HDPE anti-slip road paving panels are flat plastic mats with reinforced internal structure and textured surfaces. They are laid directly on grass, soil, sand, gravel or asphalt to create temporary traffic routes and working platforms for vehicles, cranes and equipment.

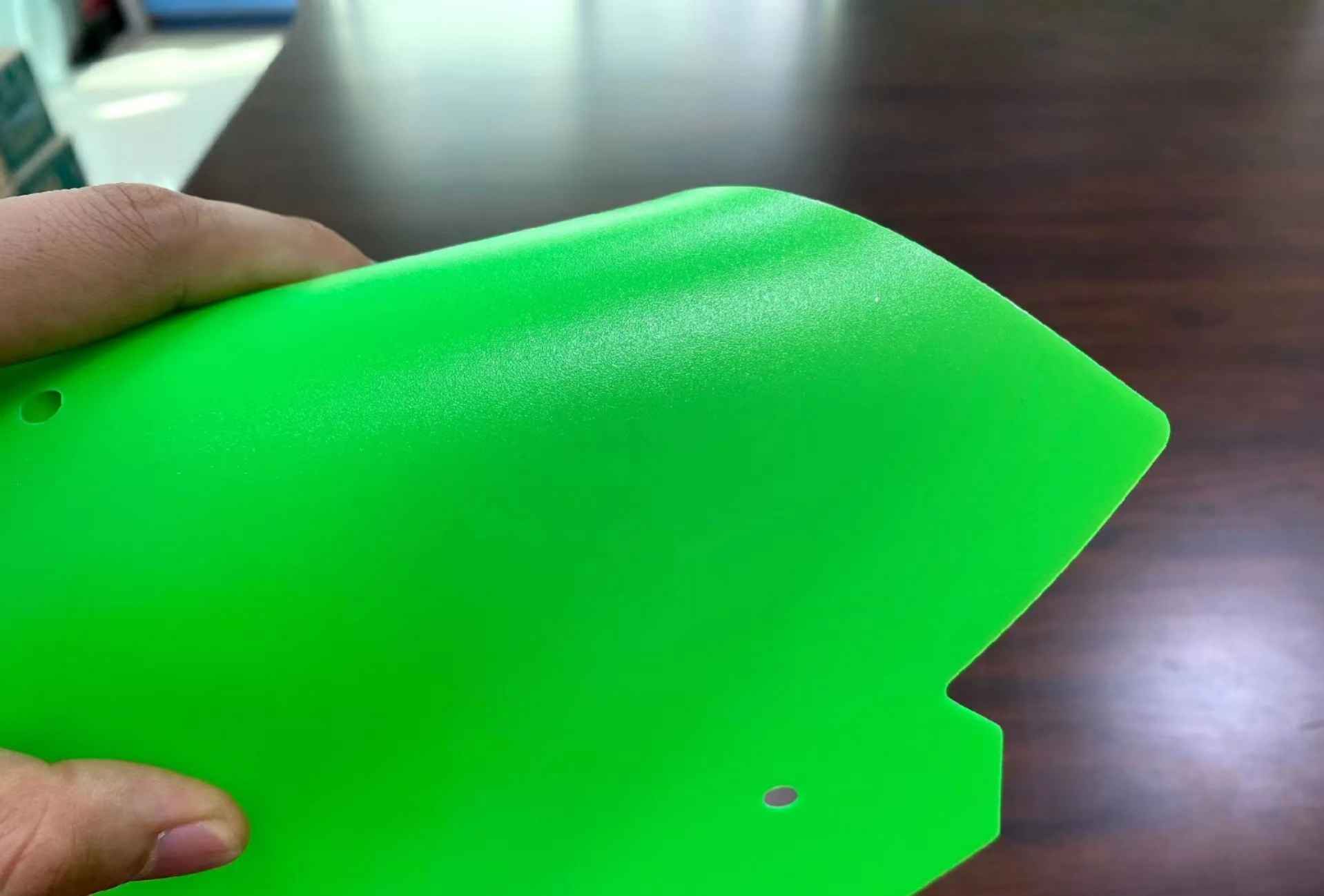

- Material: High-density polyethylene (HDPE), optionally UV-stabilized for outdoor use.

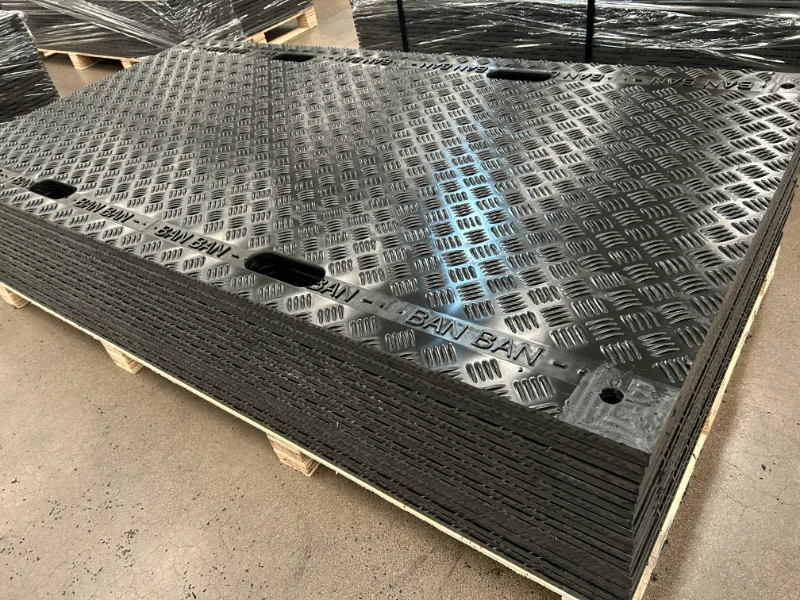

- Design: Single- or double-sided anti-slip patterns for tires and pedestrians; chamfered edges on request.

- Installation: Panels can be deployed quickly and connected with metal or plastic connectors to form a continuous surface.

2. Key Features

Ground Protection & Load Distribution

- Reduces ground damage: Spreads axle loads over a larger area, minimizing rutting and compaction on soft soils.

- Protects existing surfaces: Prevents scuffing and cracking of grass, paving, asphalt and other finished surfaces.

- Suitable for various terrains: Performs on mud, wet grass, sand, gravel and mixed ground conditions.

Safety & Anti-Slip Performance

- Textured patterns: Raised studs or tread designs enhance grip for tires and tracks in wet or slippery conditions.

- Pedestrian-friendly: Optional walking-side texture improves safety for workers and visitors.

- Stable platform: When properly connected, panels form a stable, continuous working surface for lifting equipment and vehicles.

Durability & Handling

- Impact-resistant HDPE: Tough material resists cracking and breaking under repeated vehicle loads.

- Corrosion-free and rot-proof: Will not rust, rot or absorb water, suitable for long-term outdoor storage and use.

- Lightweight vs. steel: Easier manual handling; fewer lifting devices required on site.

3. Typical Applications

- Construction sites: Temporary access roads for trucks and concrete mixers, crane pads and equipment platforms.

- Utilities & infrastructure: Access routes for power line maintenance, pipeline installation, telecom works and civil engineering.

- Oil & gas / mining: Working pads and access tracks in oilfields, exploration sites and quarries.

- Events & temporary parking: Temporary car parks, pedestrian walkways and service routes for festivals, exhibitions and outdoor events.

- Landscaping & turf protection: Protects lawns and landscaped areas during maintenance, construction and events.

4. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material | High-density polyethylene (HDPE) | UV-stabilized grades available for long-term outdoor use |

| Panel Size | Common sizes around 1–4 m in length and width | Custom dimensions available to match transport and site conditions |

| Thickness | Typically from approx. 12 – 40 mm | Thicker panels for higher loads or more demanding ground |

| Load Capacity | From light-duty pedestrian to heavy vehicle use | Design matched to project load and subgrade conditions |

| Surface Pattern | Raised studs, tread patterns or custom anti-slip designs | Single- or double-sided patterns available |

| Color | Black, grey or custom colors | Color options for branding or visibility |

| Connection System | Steel or HDPE connectors, pins or links | Ensures alignment and stability between panels |

| Service Environment | Outdoor; mud, grass, sand, gravel and paved ground | Resistant to water, most salts and common site chemicals |

| Handling | Manual handling or with lifting equipment | Optional hand holes or lifting points on panels |

| Main Industries | Construction, utilities, oil & gas, events, landscaping | Reusable ground protection for multiple projects |

For HDPE anti-slip road paving panels, please provide your application scenario, expected axle load or vehicle type, ground condition, required panel size, quantity and connection preference. We can help you choose the right panel design and supply matched connectors and accessories for your project.