1. Product Overview

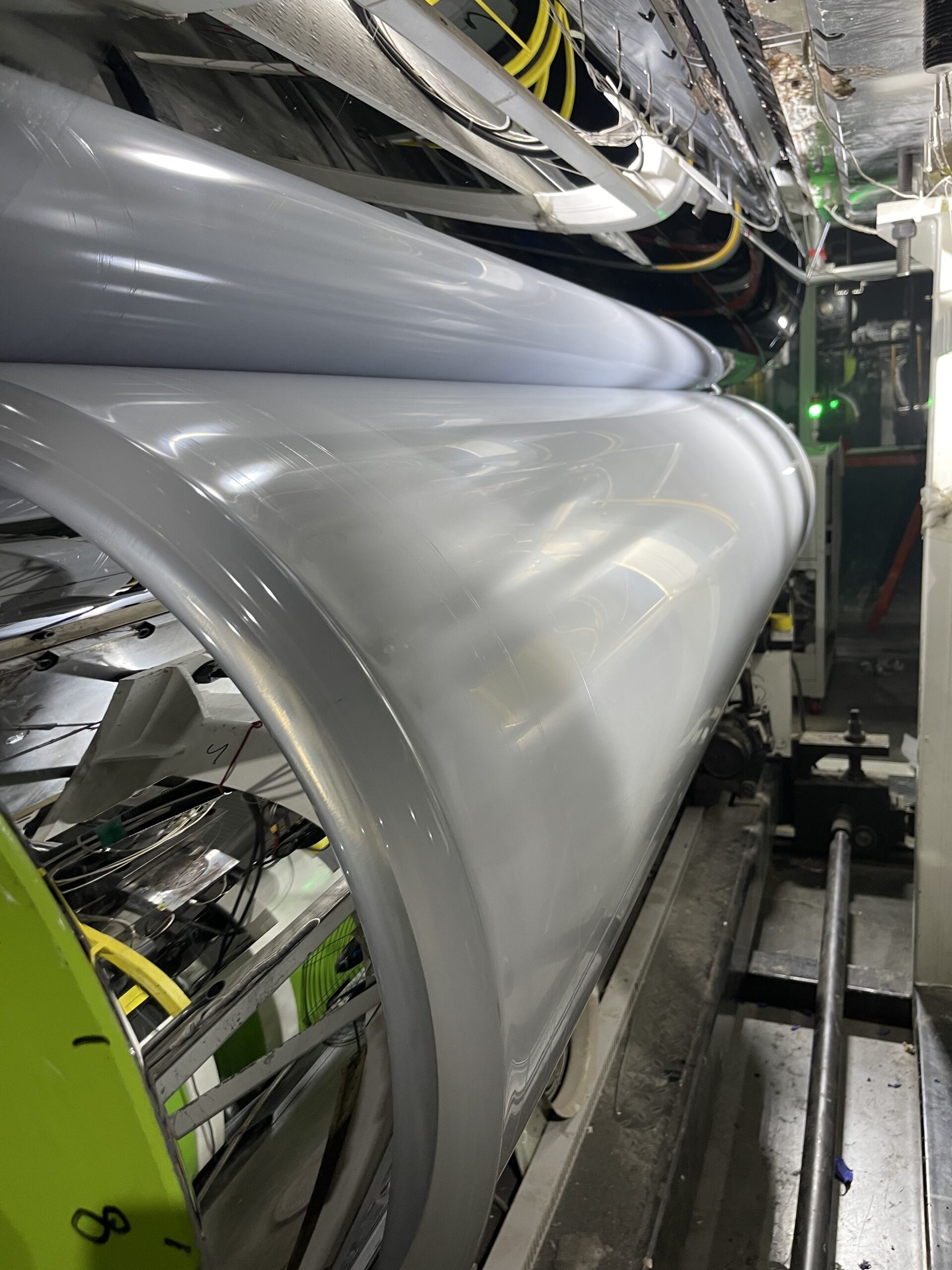

PPR (Polypropylene Random Copolymer) Sheets are extruded thermoplastic boards with a balanced combination of stiffness, toughness and hot-water performance. The random copolymer structure improves impact strength and stress-crack resistance compared with homopolymer PP, especially under typical service temperatures and pressures in water and process systems. This makes PPR sheets suitable for both industrial installations and building applications where long-term reliability and low maintenance are critical.

- Uniform thickness and flatness: Supports accurate machining, reliable sealing and easy installation on frames or supports.

- Smooth, clean surface: Easy to wash down, with low tendency to scale or accumulate dirt.

- Low water absorption: Maintains mechanical properties and dimensions even in humid or submerged conditions.

2. Key Features

Mechanical & Physical Properties

- Low density: Lightweight material that reduces structural load and simplifies lifting, transport and installation on site.

- Good impact resistance: Withstands daily knocks and vibration, suitable for panels, guards and structural components.

- Dimensional stability: Maintains shape under typical operating temperatures and loads when correctly supported.

Chemical & Temperature Resistance

- Corrosion resistance: Suitable for many inorganic acids, alkalis and salts commonly found in process, water-treatment and cleaning media.

- Hot & cold water capability: Designed to work within the normal PPR temperature range for hot and cold water service, HVAC and process piping systems.

- No rust or scaling: Will not rust, pit or form scale as many metallic materials do, helping to keep systems clean and low-maintenance.

Processing, Hygiene & Safety

- Excellent weldability: Can be joined by hot-air welding, butt welding and other thermoplastic welding methods to build tanks, ducts and complex fabricated equipment.

- Easy to machine: Can be cut, drilled, routed and CNC machined with standard plastic processing tools.

- Clean and low-odor: Smooth, non-toxic surface suitable for many environments requiring cleanliness or easy disinfection.

3. Typical Applications

Industrial Applications

- Chemical & wastewater treatment: Liners and panels for tanks, channels, launders and tanks exposed to corrosive liquids.

- Process equipment: Structural and protective panels for scrubbers, filters, dosing systems and other environmental or chemical equipment.

- Industrial protection: Machine guards, splash shields, lightweight covers and barrier panels.

Construction & Building Services

- Water & HVAC systems: Panels, covers and support boards associated with PPR piping in buildings and technical rooms.

- Interior technical areas: Wall panels, equipment backboards and protective cladding in plant rooms, pump rooms and utility spaces.

- Infrastructure projects: Sheets used around water, HVAC or service installations where corrosion resistance and low weight are important.

4. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material | PPR (polypropylene random copolymer) | Virgin material or specified industry grade |

| Thickness | Approx. 3 – 40 mm | Special thicknesses on request |

| Width | Commonly 1000 – 2000 mm | Max. width depends on extrusion capability |

| Length | Standard sheet lengths or custom cut-to-size | Cutting optimization possible according to drawings |

| Color | Grey, green, white or custom colors | Color coding for media, zones or branding |

| Surface Finish | Smooth or lightly textured | Textured surface helps hide scratches and wear |

| Chemical Resistance | Many acids, alkalis and salts | Check compatibility for strong oxidizing agents and special solvents |

| Water Absorption | Very low | Suitable for humid, wet or immersion applications |

| Service Temperature | Typical PPR hot & cold water range | Exact limit depends on pressure, mechanical load and safety factor |

| Fabrication Options | Cutting, drilling, CNC machining, hot-air welding, butt welding | Supports fabrication of finished tanks, ducts and custom components |

| Main Industries | Chemical, wastewater, building services, HVAC, machinery | One sheet solution covering multiple sectors |

To select the right PPR sheet for your project, please provide details of your application, working medium, temperature, thickness, sheet size, quantity and design drawings. We will recommend suitable PPR specifications and offer fabrication and quotation support tailored to your needs.