1. Product Overview

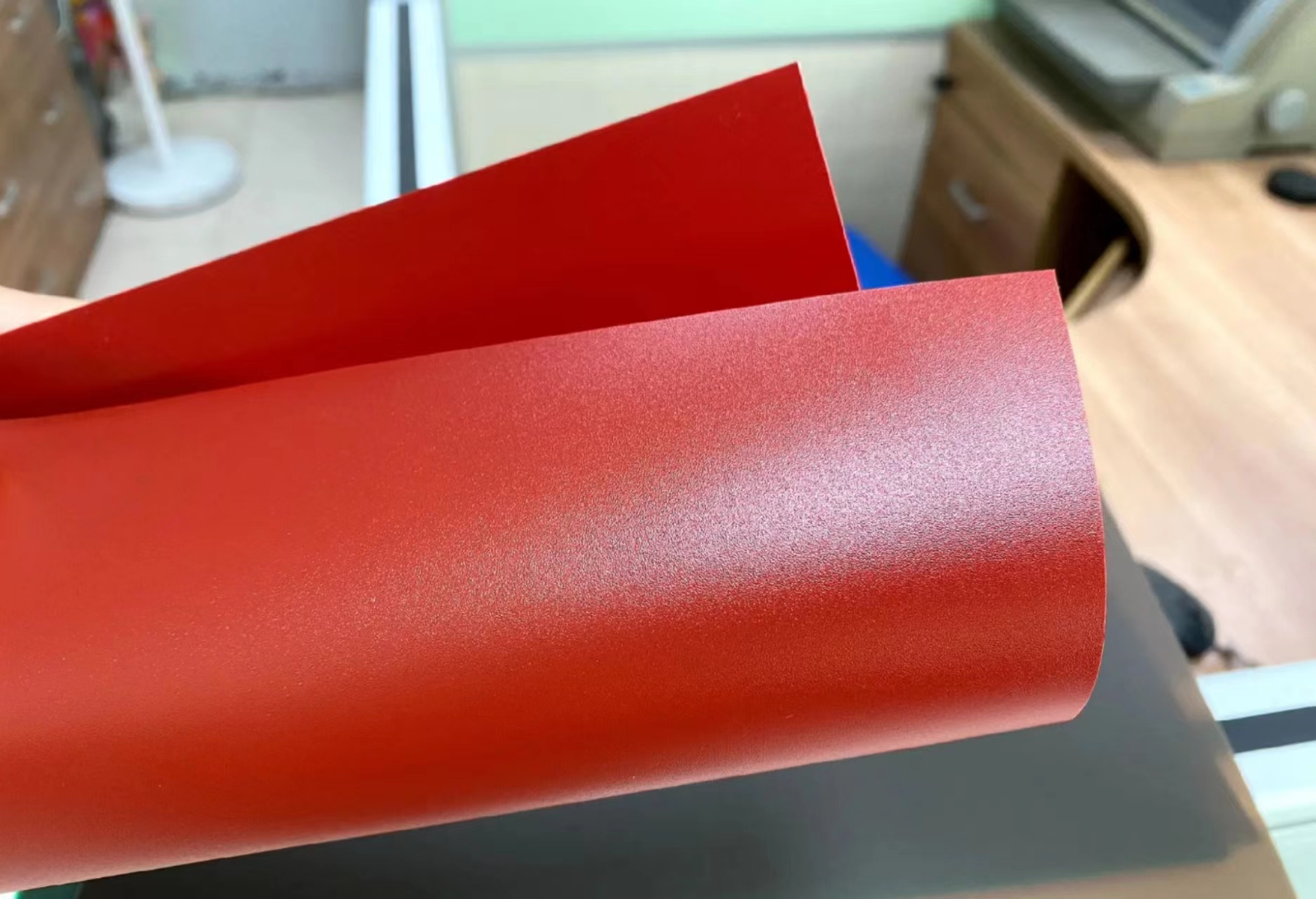

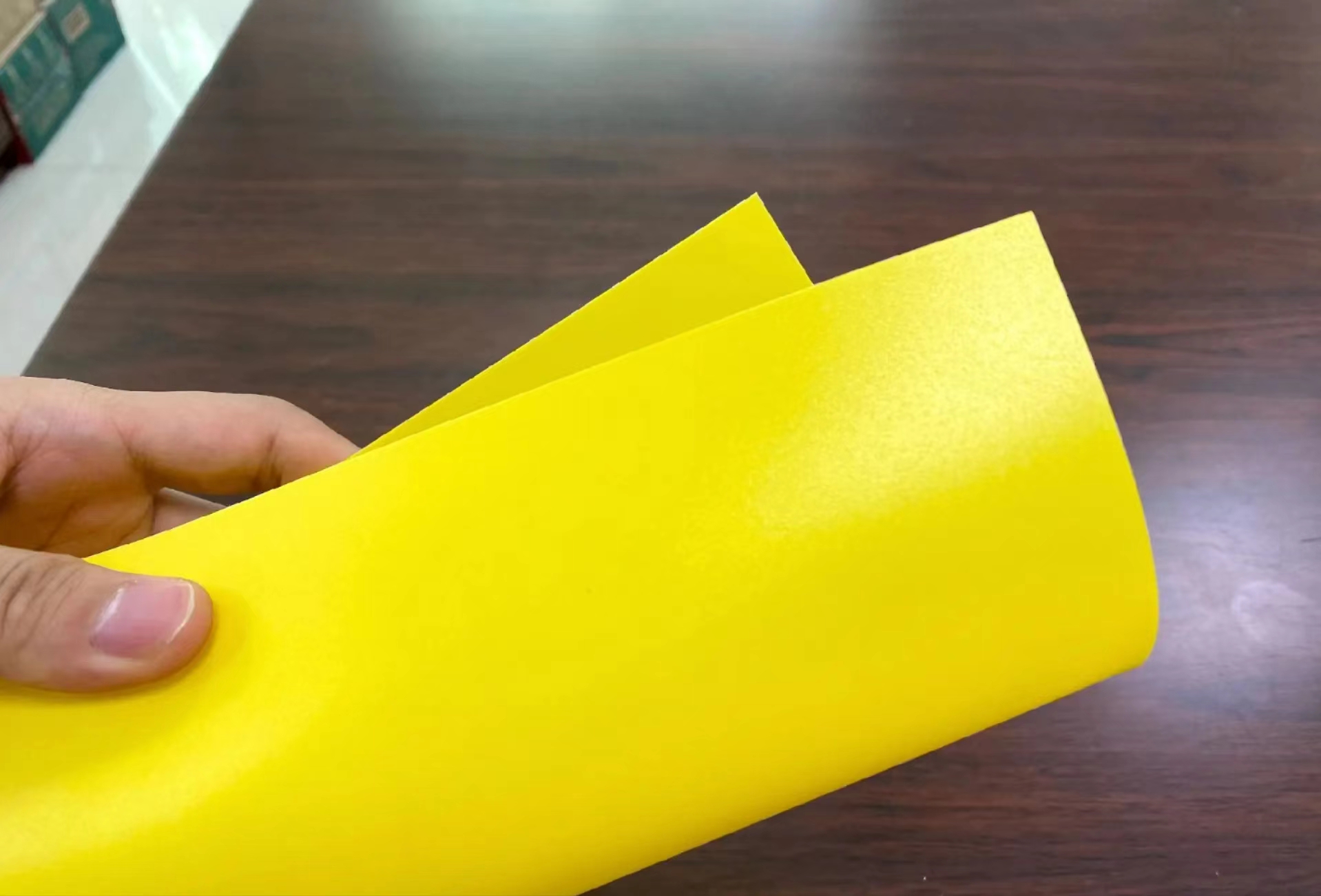

PP sheets are extruded polypropylene boards with a smooth or lightly textured surface and uniform thickness. Polypropylene combines low density with good stiffness and chemical resistance, making PP sheets a cost-effective alternative to metal or PVC in many industrial and environmental applications.

- Material type: Polypropylene (PP), typically homopolymer for higher stiffness or specified grades on request.

- Appearance: Flat boards with good flatness and consistent thickness for reliable fabrication and assembly.

- Processing: Suitable for cutting, welding and machining into finished parts or complete units.

2. Key Features

Mechanical & Physical Properties

- Low density: Much lighter than steel or other metals, reducing structural load and easing on-site handling.

- Good stiffness: Maintains shape and dimensional stability when correctly supported in panels and structural components.

- Impact resistance: Adequate toughness for most industrial uses, such as guards, covers and housing panels.

Chemical & Thermal Properties

- Chemical resistance: Suitable for many inorganic acids, alkalis and salts, commonly used in chemical, plating and wastewater equipment.

- Corrosion-free: Will not rust or corrode like metal; no metal ion contamination of media.

- Temperature performance: Designed to operate within the typical PP temperature range in industrial environments.

Processing, Hygiene & Safety

- Excellent weldability: Hot-air and butt welding allow assembly of tanks, ducts, scrubbers and structural components.

- Easy machining: Can be cut, drilled, routed and CNC machined with standard plastic-fabrication equipment.

- Clean surface: Smooth, low-odor surface that is easy to clean and maintain; suitable for many general industrial and semi-hygienic applications.

3. Typical Applications

- Chemical industry: Tanks, plating lines, scrubbers, fume hoods, splash guards and corrosion-resistant linings.

- Environmental & wastewater treatment: Panels and linings for treatment tanks, launders, channels and covers.

- Ventilation & exhaust systems: Exhaust ducts, vents and housings used in corrosive or humid environments.

- Mechanical & industrial equipment: Machine guards, covers, protective plates and lightweight structural parts.

- General fabrication: Custom components, panels and housings produced by welding and machining PP sheets according to drawings.

4. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material | Polypropylene (PP) | Homopolymer or specified grades according to project |

| Thickness | Approx. 3 – 40 mm | Special thicknesses available on request |

| Width | Commonly 1000 – 2000 mm | Max. width depends on extrusion line capability |

| Length | Standard sheet length or custom cut-to-size | Cutting optimization available according to drawings |

| Color | Grey, natural, white or custom colors | Color coding for zones or media identification |

| Surface Finish | Smooth or lightly textured | Textured finish can help hide scratches |

| Chemical Resistance | Many acids, alkalis and salts | Check compatibility for strong oxidizing agents and specific solvents |

| Water Absorption | Very low | Suitable for humid, splash or immersion environments |

| Service Temperature | Typical PP operating range | Exact limit depends on load, safety factor and application |

| Fabrication Options | Cutting, drilling, CNC machining, hot-air welding, butt welding | Supports fabrication of tanks, ducts and custom equipment |

| Main Industries | Chemical, environmental, ventilation, machinery, general industrial | One sheet solution for multiple sectors |

For PP sheet production and customization, please provide your application scenario, working medium and temperature, required thickness and size, quantity and drawings. We will recommend suitable PP material and offer machining, welding and fabrication services to support your project.