1. Key Characteristics of PPH Board

Mechanical & Physical Properties

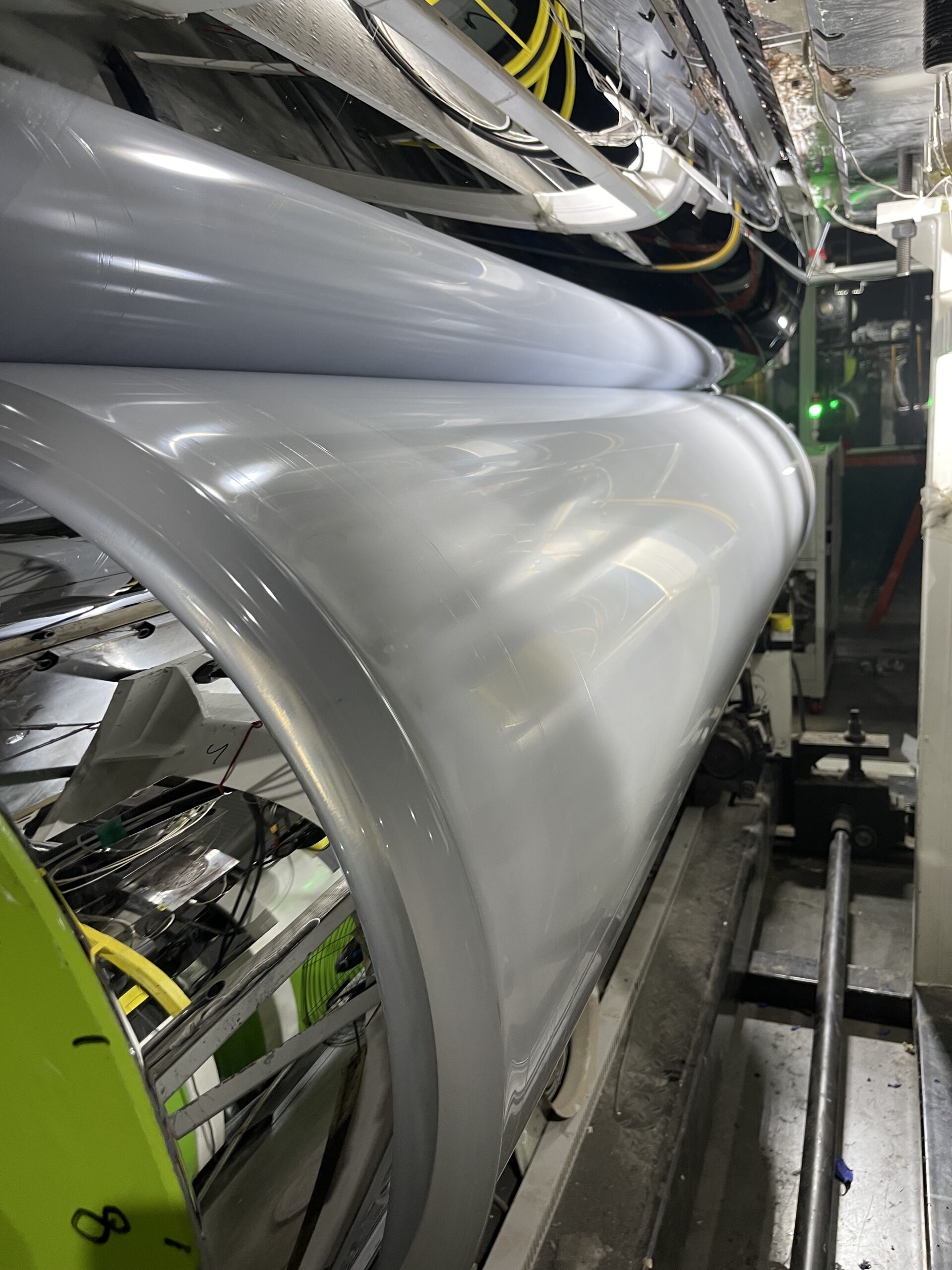

PPH (polypropylene homopolymer) offers a good balance of stiffness and toughness. Compared with copolymer PP, homopolymer PPH has higher rigidity and better heat resistance, which is beneficial for structural panels and tanks that must maintain shape at elevated temperatures. The material is lightweight, with a density much lower than steel, reducing overall equipment weight and easing installation.

- Good stiffness: Maintains shape and dimensional stability under normal operating loads.

- Impact resistance: Sufficient toughness for most industrial applications; suitable for tank walls, ventilation panels and machine guards.

- Low density: Easier handling on site and lower structural load compared with metal materials.

Chemical & Thermal Properties

PPH boards are widely used in chemical and environmental equipment because of their strong resistance to many corrosive media. They perform well in many acid and alkali environments, making them suitable for long-term use in scrubbers, plating lines and wastewater treatment units.

- Chemical resistance: Excellent resistance to many inorganic acids, alkalis and salts; suitable for exhaust gas scrubbing, chemical tanks and etching lines.

- Temperature performance: Better heat resistance than many general plastics, suitable for warm liquids and process gases within the typical PP temperature range.

- Low water absorption: Maintains mechanical properties and dimensions in humid or wet service.

Processing & Hygiene

- Good weldability: Hot-air welding and butt welding can be used to assemble tanks, ducts, scrubbers and custom equipment.

- Easy fabrication: Boards can be cut, drilled, routed and machined into complex parts using standard plastic fabrication tools.

- Clean and smooth surface: Non-toxic, easy to clean, with low contamination and low odor, suitable for many industrial and semi-hygienic environments.

2. Typical Applications of PPH Board

- Chemical industry: Chemical storage tanks, reaction tanks, scrubbers, pickling lines, plating tanks, fume hoods and corrosion-resistant ducting.

- Environmental & wastewater treatment: Tanks, settling units, launders, covers and structural parts in wastewater and gas-treatment systems.

- Ventilation & exhaust systems: Corrosion-resistant air ducts, elbows, plenums and ventilation boxes used in chemical or coastal environments.

- Electronics & surface treatment: Tanks and equipment housings for PCB production, etching and cleaning lines.

- General industrial: Machine guards, splash shields, structural panels and lightweight protective covers.

3. Specifications & Customization Options

| Item | Typical Range / Options | Notes |

|---|---|---|

| Material | PPH (polypropylene homopolymer) | Virgin material or specified industrial grade |

| Thickness | Approx. 3 – 40 mm | Other thicknesses available on request |

| Width | Commonly 1000 – 2000 mm | Max. width depends on production capability |

| Length | Standard lengths or custom cut-to-size | Cutting and panel optimization available |

| Color | Grey, natural, white or custom colors | Color coding for media, zones or branding |

| Surface Finish | Smooth or lightly textured | Textured surface can help hide scratches |

| Chemical Resistance | Many acids, alkalis and salts | Check compatibility for strong oxidizing media and specific solvents |

| Water Absorption | Very low | Suitable for humid, wet or immersion conditions |

| Service Temperature | Typical PP operating range | Exact limit depends on pressure, load and safety factor |

| Fabrication Options | Cutting, drilling, CNC machining, hot-air welding, butt welding | Supports assembly into complete tanks, ducts and custom equipment |

| Main Industries | Chemical, environmental, surface treatment, electronics, machinery | One board material for multiple sectors |

If you need PPH boards for chemical tanks, scrubbers, ducts or other corrosion-resistant equipment, please send us your medium, temperature, thickness and size requirements, quantity and drawings. Our team will help you choose the right PPH configuration and provide quotation and fabrication options for your project.